Innovation in Four Dimensions: Zahner Research Team Presents at AECtech

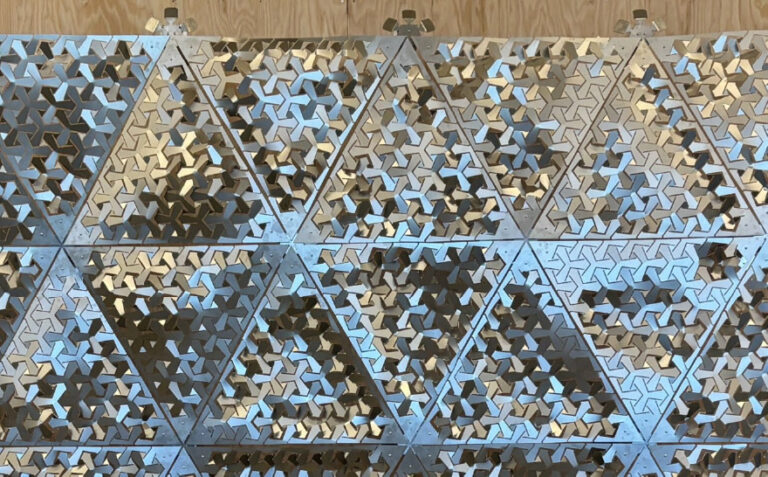

At the recent AECtech 2025 Conference, part of a unique, week-long conference that brings together designers, engineers, technologists, and builders from around the world to advance innovation across the built environment, Zahner Lead Research and Development Engineer, Burcin Nalinci, presented “Innovation in Four Dimensions: From Tacit Craft to Computational Knowledge.”