Anodization turn porous raw aluminum into a durable surface that is an excellent option for interior and exterior applications. Anodization also provides the opportunity to incorporate metallic dyes into the finish, offering a variety of colors without detracting from the distinctive metallic quality of aluminum.

Standard Finishes

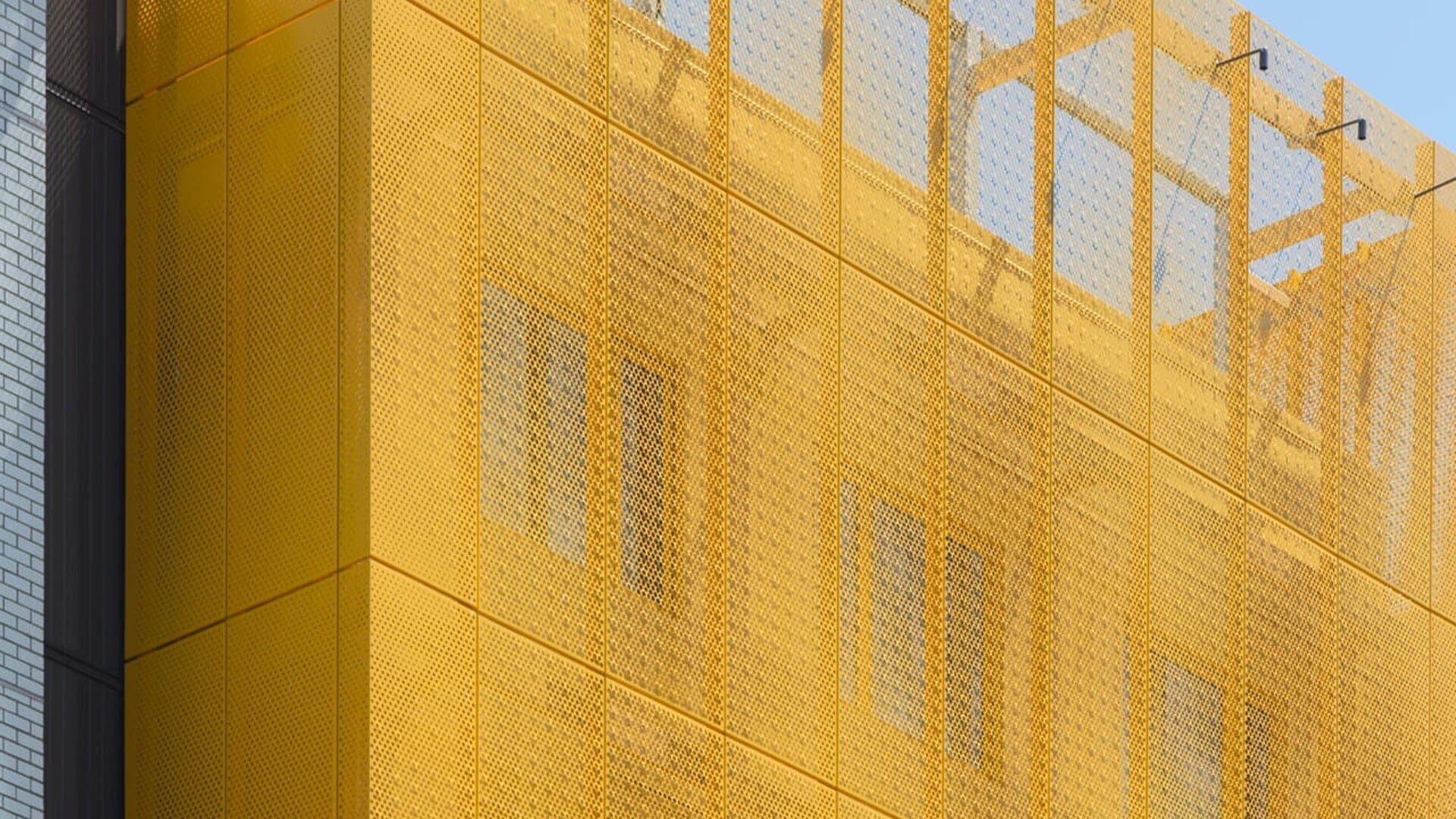

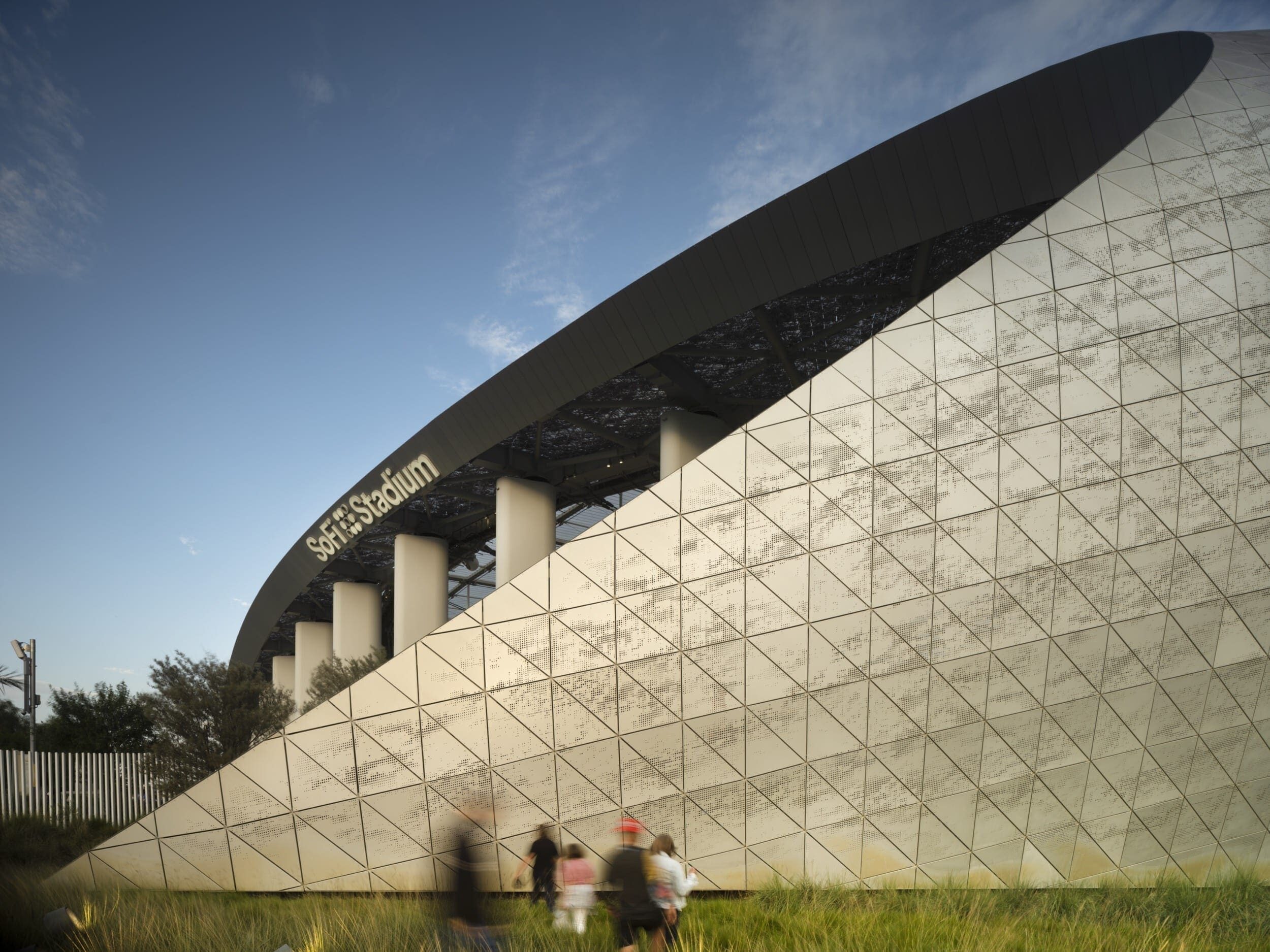

A selection of anodized aluminum finishes are available for specification with one of Zahner’s perforated metal panel systems. See the swatches below for available finishes.

Standard Anodized Finishes

Standard anodized aluminum finishes are available for use with Zahner ImageWall® and ImageLines® perforated metal panel systems.

Custom Finishes

When you bring your project to the Zahner Custom Solutions team, we can help you source from a diverse range of anodized aluminum finishes, facilitate sourcing, and provide purchase timing recommendations based on fluctuations in market prices for different metals.

Please note: We do not offer supply-only sheets of anodized aluminum, but we are happy to custom fabricate based upon your project’s needs. We selectively partner with vendors offering the highest quality materials available.

Properties of Anodized Aluminum and Its Use in Architecture

Material Properties

Anodized aluminum is a method of passivating an aluminum alloy to prevent the material from oxidizing. While raw aluminum is a highly versatile and durable surface, if left to weather naturally it will turn to a light gray tone; sometimes, depending on the atmospheric pollution, dark gray mottling will be intermixed on the surface.

Raw aluminum, unlike stainless steel, will not sustain a polished surface when exposed to the atmosphere. Oxides form on the surface, dulling the finish. Frequent cleaning and polishing are required to sustain a luster. In seaside regions, unprotected aluminum will pit extensively.

By anodizing an aluminum surface, this atmospheric corrosion can be reduced, but not eliminated. Anodizing provides a thin aluminum oxide layer, which will deteriorate over time. Depending on the thickness and quality of the anodization, the surface should last 10-20 years.

Anodizing the surface of aluminum provides a layer of protection from scratches, but again, this material is not impervious to scratches due to its softness when compared with metals that rank harder on the Rockwell Hardness Scale.

Anodized finishes enhance the natural oxide film and can impart colors to the aluminum surface through chemical reactions with the alloying components or by the addition of colored dies or metal salts into the pores.

Color Anodization

Similar to titanium, a range of pastel colors can be achieved with anodized aluminum. There are a few processes which can be used to achieve colors and tones, including dyes, salts, and electrolytic deposition.

Aluminum is a porous material. Its atomic structure is not very dense, and this allows it to be very lightweight. This structurally consistent porosity also provides the material with a good substrate to apply a metalized coloring using salts, electrical currents.

Some alloys of aluminum take color better than others, and its reflectivity can be adjusted based on the iron content in the alloy.

Anodized Aluminum and Corrosion

Anodized aluminum is more corrosion resistant than natural, unfinished aluminum. There are, however, certain concerns and contaminants that will affect anodized aluminum, causing discoloration and fading. Contact with salts, lime, concrete, and other masonry materials can cause corrosion of aluminum. Protect direct contact with these surfaces using layers of felt, neoprene or paints.

Both raw and anodized aluminum parts will stain when water is allowed to wet the surface and slowly dry. Major problems arise when moisture has entered between faces of aluminum sheets or panels. On natural aluminum materials, dark gray to black stains will quickly develop. On anodized material, watermarks and grayish blotches can develop. The removing and cleaning of surfaces blotches is very difficult and usually more expensive than replacement.

Under magnification, anodic coatings exhibit microscopic cracks. These cracks, also known as surface crazing, result from differential thermal movement of the anodized surface film and the base metal. This crazing is not considered detrimental to the overall protection the anodized film provides.