The Proliferation of Perforated Metal in Architecture

Perforated metal has a long history in industrial applications such as filtration, screening, and grating. Its use in architecture, however, is comparatively recent. Over the last several decades, perforated metal has evolved from a purely utilitarian material into a powerful architectural medium—capable of conveying imagery, texture, and light at the scale of buildings.

Zahner has been at the forefront of this evolution. Beginning in the twentieth century and accelerating in the early 2000s, Zahner helped redefine what perforated metal could be by integrating advanced engineering, digital design tools, and fabrication technologies. A pivotal moment in this shift occurred in 2005 with the de Young Museum in San Francisco.

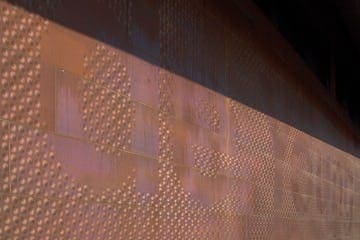

The first architectural project to use custom imagery translated into algorithmically placed perforations across a building façade, Zahner was chosen by architects Herzog & de Meuron to realize a design that would mirror the foliage of the surrounding Golden Gate Park in the perforated screen facade of the de Young Museum.

Since then, Zahner has completed hundreds of projects utilizing custom perforated metal, contributing to what can be considered a renaissance in the material—one where performance, craft, and artistic expression converge.

Photo courtesy James Carpenter Design Associates.

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © Mike Sinclair

Photo © Jah Hendrix

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © A. Zahner Company

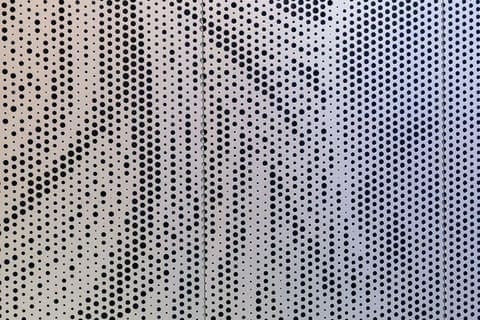

Evolving Perforation Technology

ZIRA is Zahner’s patented system for translating images, graphics, and patterns directly into metal surfaces. Rather than relying on standard, repeating perforation patterns, ZIRA allows designers to use their own imagery—photographs, drawings, gradients, or custom graphics—to generate highly specific perforation layouts.

ZIRA stands for Zahner Interpretive Relational Algorithm and is protected under U.S. Patent No. 7,212,688 B2. The system was developed to streamline the creation of complex custom perforations and selective embossing, enabling precision and efficiency at any project scale.

At its core, ZIRA bridges the gap between visual intent and fabrication reality. Images are interpreted algorithmically and converted into data that drives perforation size, spacing, and placement, producing metal surfaces that respond to light, depth, and perspective in sophisticated ways.

ZIRA technology continues to evolve, supporting not only perforation but also selective embossing and cutting. Designers can combine these techniques to create layered effects and nuanced surfaces that would be difficult—or impossible—to achieve through conventional methods.

Photography by Alexander Miller

Photo © Mike Sinclair

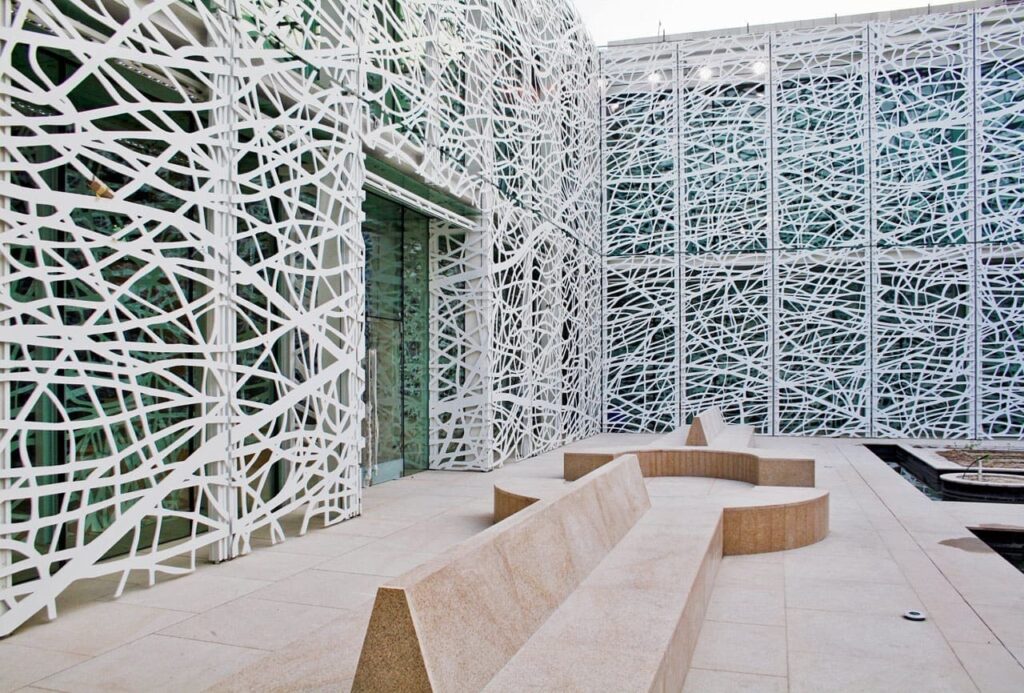

ImageWall™: A Pre-Engineered, Custom Image-to-Perforation System

One of the most accessible expressions of ZIRA technology is ImageWall, a Zahner-developed Versatile System that allows designers to create and specify custom perforated metal facades, feature walls, and screens without the cost and complexity of a fully custom-engineered ZIRA solution. ImageWall is enhanced by Zahner’s Cross-Seam Perf™ technology enables designers to create seamless imagery across panels, and Drop & Lock™, a fast and sealant-free installation system for metal panels.

More recently, Zahner introduced ImageLines™. Where ImageWall’s circular perforations provide a halftone-based aesthetic, ImageLines offers designers a brushstroke-like aesthetic through the use of rectilinear perforations that provides new opportunities to subtly direct the eye toward wayfinding points, entrances, and fenestrations.

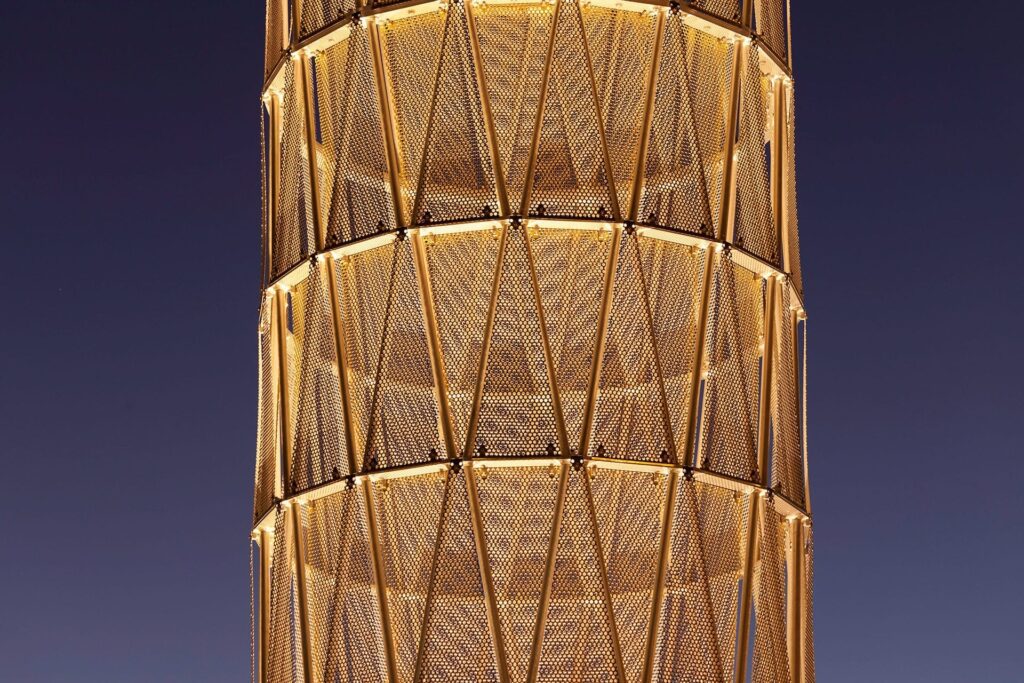

Other Applications: Perforated Metal Tubing

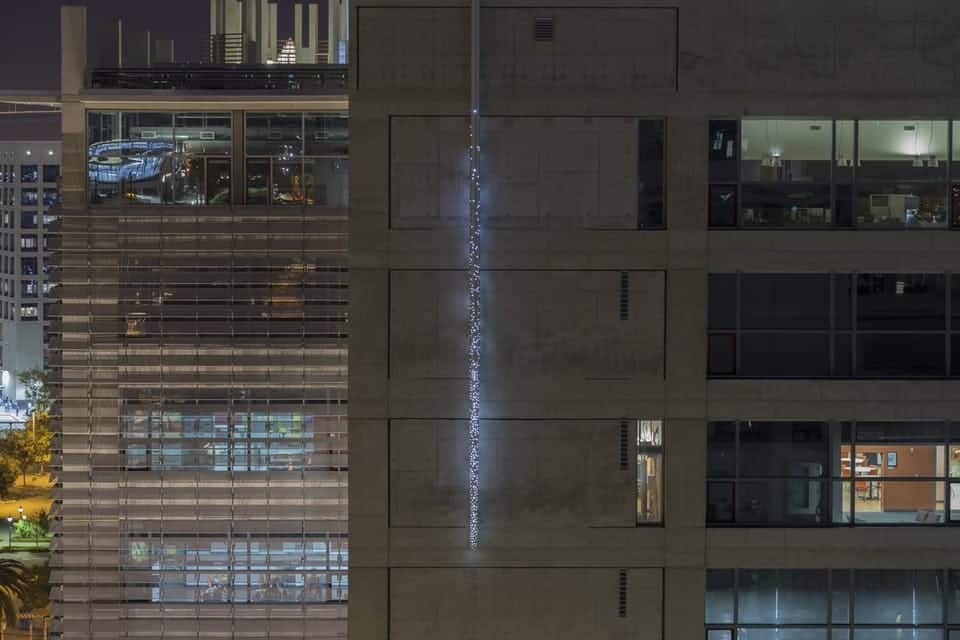

Custom perforation is not limited to flat metal surfaces. Zahner also applies ZIRA-driven perforation techniques to metal tubing, opening new possibilities for three-dimensional architectural and product applications.

Perforated metal tubing can be used to create light fixtures, sconces, hanging lamps, bollards, rails, masts, screens, and other sculptural or functional elements. The interplay of perforation, curvature, and light allows tubing to perform as both structure and visual feature.

Zahner’s engineering team collaborates closely with designers to explore these possibilities, assisting with concept development, pattern refinement, and execution. The same advanced technologies used for architectural panels are applied to tubular forms, ensuring consistency in quality and design intent across applications.

Getting Started

Working with Zahner on custom perforated metal systems is a collaborative process. Zahner engineers understand both the artistic ambitions and the technical demands of complex architectural projects. To begin developing a custom perforated design, explore the ImageWall app or contact the Zahner sales team to discuss your project.