Angel Hair is Zahner’s patented process for creating a soft, diffuse finish on stainless steel. By etching the metal with precision-controlled techniques, Angel Hair reduces the intense reflectivity of standard finishes while maintaining a refined, lustrous appearance. This smooth, uniform surface effectively scatters light, minimizing glare and heat concentration, making it ideal for architectural projects that require both functionality and elegance indoors or outdoors.

Developed to address challenges with reflective stainless steel, Angel Hair offers light diffusion with consistency. Zahner’s innovative process eliminates common issues like striping and uneven textures, creating a velvety finish that endures decades of weathering. Angel Hair is a versatile choice for architectural applications, balancing aesthetics and practicality for timeless designs.

Angel Hair Stainless Steel Manufacturing, Properties, and Applications

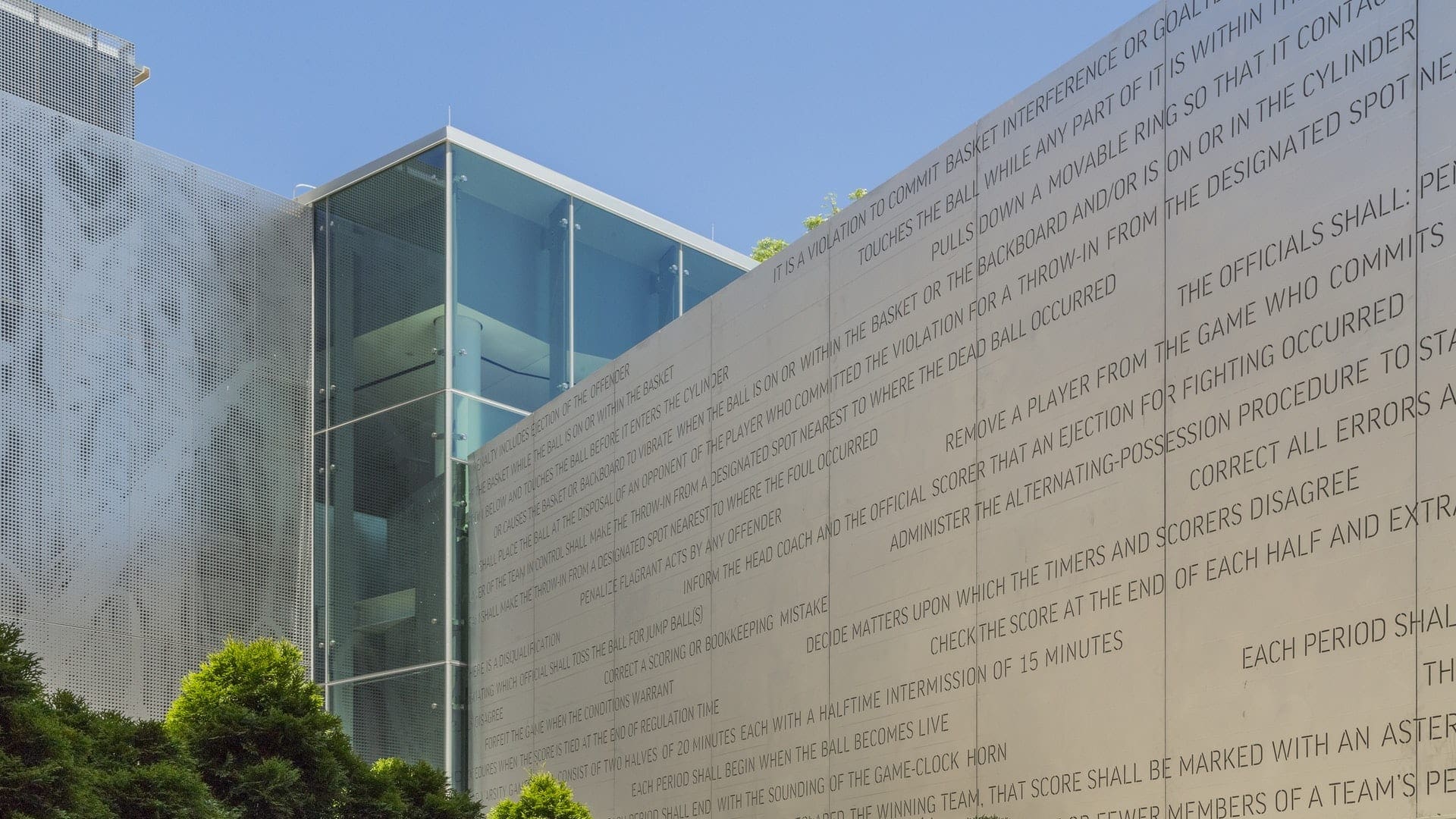

Angel Hair is a Zahner material process developed to soften the high-reflectivity of standard grain finishes. The patented process uses precision-controlled machinery to etch stainless steel with a fine grain and a dual surface, with one level of texture below another. The tiny circular scratches applied to the metal alloy will disrupt symmetry to produce a consistent luster, eliminating striping and scalloping effects. Available on a variety of metal alloys, this is the finest, smoothest, and most uniform light-diffusion metal surface available for architectural metal.

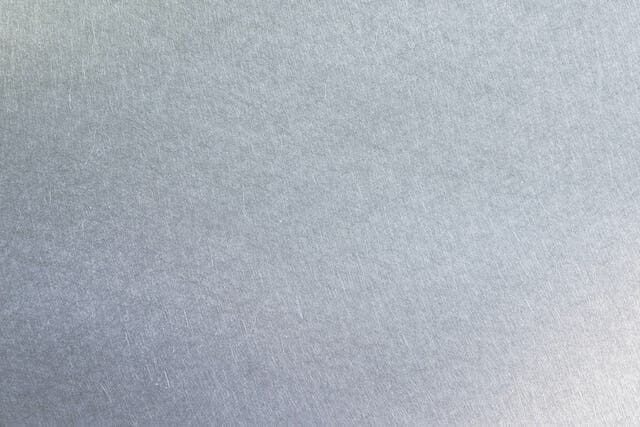

Close-up of Angel Hair Stainless Steel sheet material.

Photo © A. Zahner Company

This surface was first developed as a custom product by Zahner as a solution to the reflective nature of standard finishes on stainless steel. Working with Frank Gehry on a number of projects, the Zahner team recognized that these parabolic shapes combined with the intense reflectivity of stainless steel would result in concentrated heat and blinding light. Angel Hair scatters the light, providing the most diffused surface while maintaining the metal’s reflective appearance.

The Angel Hair Difference

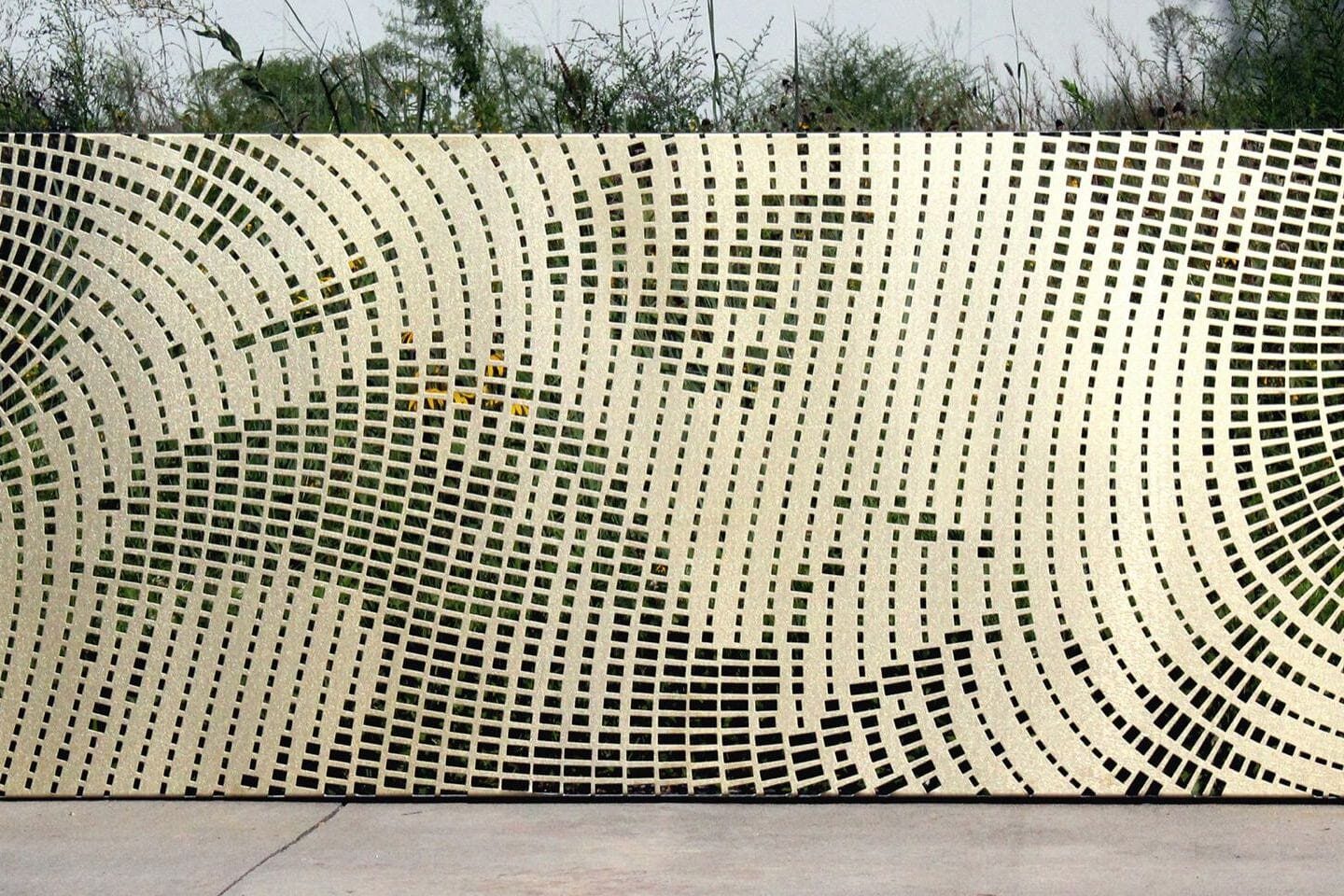

Since first developing this product years ago, other manufacturers have begun to offer variant polishes and “vibration-finishes” which attempt to replicate the Zahner Angel Hair. When compared to other metals from up close, you can see striping patterns and heavy marks in the “vibration” surfaces offered by other manufacturers.

Angel Hair® Stainless Steel by Zahner.

Photo © A. Zahner Company

“Vibration” finish offered by industry manufacturers.

Photo © A. Zahner Company

Dimensions and Material Data

This surface is available in sheet and plate in any thickness. The sheet materials come in 48″ and 60″ typical maximum widths, and are available in several alloys based on performance in different environments. Custom shapes and three-dimensional forms are possible with the material. See product information and specifications here.

To understand the reflectivity, take a look at the comparative gloss readings when compared with standard reflective or GB-60 finishes. This data shows Angel Hair Process applied to a base material with a 2B finish. If applied Angel Hair to a No. 8 polished base material or a bright annealed base material, you can achieve a variety of ambient reflective properties and appearances.

Maintenance for Angel Hair on Stainless Steel

Angel Hair on stainless steel is easily maintained. Stainless steel, if properly detailed and installed, will outlast most materials by a great margin. The polish provided by Angel Hair furthers this longevity by providing the metal surface with a greater ease of repairability. Should the metal get damaged, scratched, or abraded, the material can be easily polished by a Zahner technician using a field-version of the Angel Hair polishing system.