Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

While it’s sometimes possible to order custom sheet sizes directly from a mill, that path comes with longer lead times and minimum quantity requirements. If scope and design allow, working with standard sheet sizes is the most efficient way to maintain both schedule, budget, and quality.

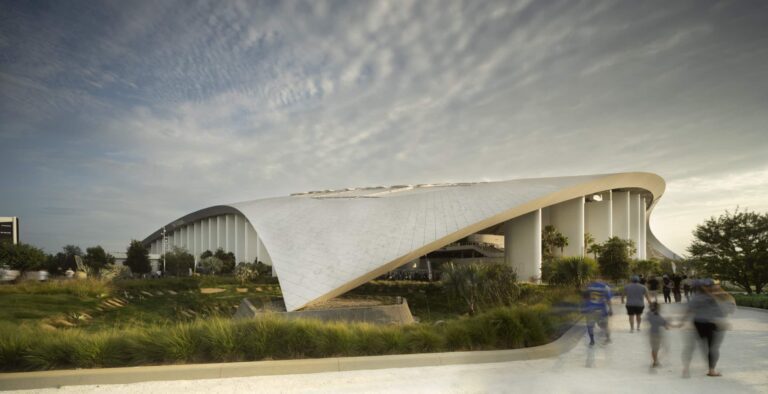

United Methodist Church of the Resurrection in Leawood, Kansas.

Photo © A. Zahner Company.

Understanding the Finer Points of Material Dimensions and Material Usage

Our Flat Seam Panel System involves alternating up-and-down hemmed edges on each panel. This adds roughly 3 inches to both the width and height of each panel beyond the visible surface.

For example, if your design calls for a 24″ x 72″ face dimension, the actual sheet metal cut will need to be 26.25″ x 74.25″. If you’re using a 36″ x 96″ copper sheet, this panel size may result in significant leftover material that cannot be reused, driving up both cost and waste.

By adjusting your panel dimensions slightly, without compromising your design intent, you can often nest more panels per sheet and boost yield.

The new Margaret M. Walter Wing of the Columbus Museum of Art features Zahner’s preweathered Star Blue™ copper.

Photo by Jeremy Purser | Photo © A. Zahner Company.

Detail of the Eugene Federal Courthouse facade, featuring Zahner’s Angel Hair Stainless Steel.

Photo © A. Zahner Company.

Sample Yield-Optimized Panel Sizes for Flat Seam

Some efficient, low-waste panel size examples that nest nicely on a 36″ x 120″ copper sheet include:

- 20″ x 31.5″ (5 per sheet, rotated)

- 13.875″ x 36″ (6 per sheet)

- 30″ x 36″ (3 per sheet)

- 13.875″ x 115.5″ (2 per sheet)

These sizes account for hemming, kerf spacing, and other factors to ensure optimal material yield.

15 Renwick residential development in Manhattan.

Photo by Jeremy Purser | Photo © A. Zahner Company.

Detail of the New Hunter Museum entrance.

Photo © Scott Moore

Detail of the Dirty Penny patina on copper panels.

Photo © Scott Moore

Balancing Panel Size with Labor and Appearance

Choosing the ideal panel size is a delicate balancing act between minimizing material waste, reducing fabrication labor, and maximizing aesthetic impact.

We help designers evaluate these tradeoffs and propose layout options that make the best use of selected materials.