Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

For more than 80 years, global architecture and design firm HKS has built a reputation on performance-driven design and a commitment to human-centered innovation. HKS designs places that shape experiences and enrich lives from healthcare to hospitality, stadiums to civic landmarks. One of the firm’s most dynamic expressions of that vision is its internal design lab, HKS LINE—short for Laboratory for Intensive Exploration.

Founded by Partner and CEO Elect Heath May, HKS LINE was conceived as a space to explore the boundaries of architecture, where digital design, computational thinking, and material experimentation converge.

Photo © Nic Lehoux.

Over the past decade, LINE has tackled projects across typologies and scales, from consulting on ultra-complex installations to executing end-to-end designs. In all cases, LINE aims to push architectural practice into new territory, leveraging digital tools not for novelty, but to achieve meaningful results that would be impossible through traditional means.

That appetite for experimentation naturally led HKS to partner with Zahner.

Exploration doesn’t follow a straight line. When we’re venturing into new terrain, creating a novel surface treatment or developing an entirely new delivery method, we need partners who can think like us and challenge us. Zahner does that.

— Heath May Partner and CEO Elect at HKS

From Creative Chaos to Constructive Order

May likens the innovation process to a controlled burn. Architectural firms may seek innovation, but often default to hierarchy and near-term efficiency—a dynamic that can stifle long-term creativity. HKS and Zahner take a different approach. Together, they embrace ambiguity, ask the more complex questions, and test what’s possible.

One recent example is a joint R&D exploration into selectively-applied patinas—how to create unique color patterns across a single metal sheet by varying the chemical finish. For a project with complex material and aesthetic goals, HKS needed Zahner’s patina expertise and their willingness to enter uncharted territory. “We brought our computational skills and curiosity,” said May. “Zahner brought decades of material knowledge and the engineering rigor to translate experimentation into a buildable reality. That’s what makes the relationship so valuable.”

Photo by Jesse Pacheco, ARKO | © A Zahner Company

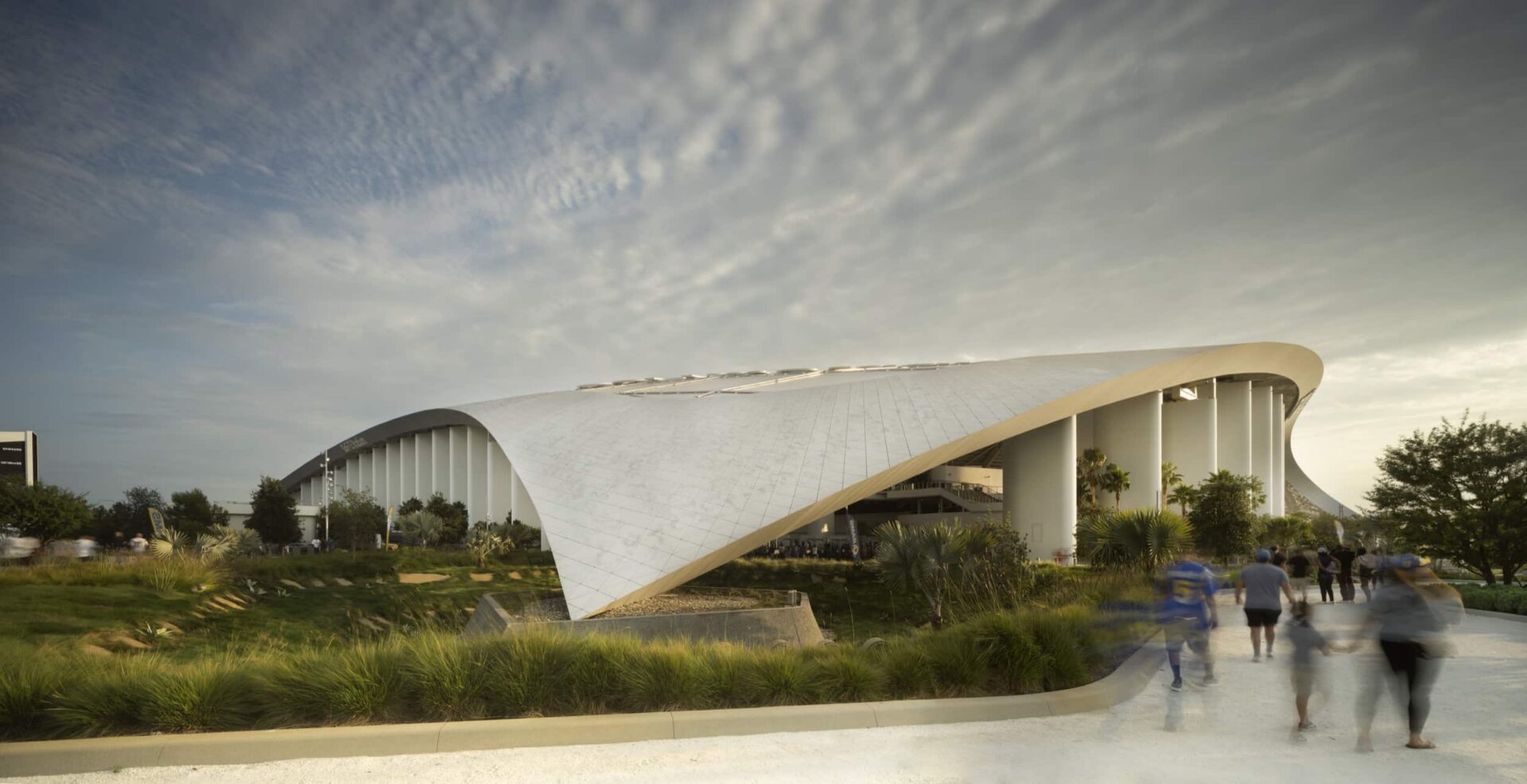

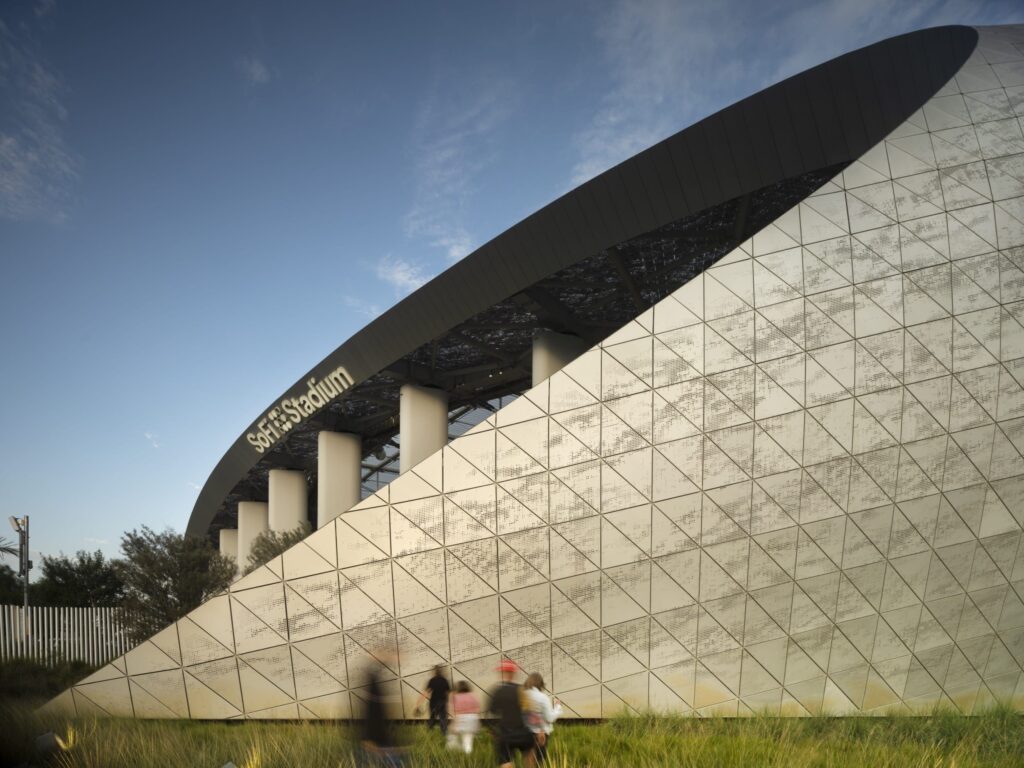

SoFi Stadium: Mass Customization at Monumental Scale

That mutual trust was forged over years of collaboration, notably with SoFi Stadium in Los Angeles. The stadium’s iconic envelope comprises over 37,000 unique aluminum panels, with no two exactly alike. The design vision called for geometry so complex that conventional drawings and models were unworkable.

Instead, James Warton, Vice President and Regional Practice Director at HKS LINE, along with Timothy Logan, Regional Practice Director and Principal at HKS LINE, developed a custom computational pipeline to deliver exact fabrication instructions—text files containing each panel’s XYZ coordinates and attributes. This deep integration between architecture and engineering allowed Zahner to fabricate precisely while reducing field issues and accelerating delivery. “In this model, we weren’t taking on more risk, we were reducing it,” said Warton. “By bypassing traditional translation layers and going directly from parametric model to fabrication, we improved quality and efficiency.”

Photo by Ramsey Attia, ARKO | © A. Zahner Company

From Stadiums to Sculptures: Pacific Plaza Pavilion

HKS and Zahner have also collaborated on another small but symbolically rich project—Pacific Plaza Pavilion in Dallas, designed in collaboration with landscape architecture firm SWA. Situated near HKS’s headquarters, the park pavilion needed to reflect the site’s history and its railroad roots.

The team created a custom perforated canopy, using Morse code to translate the names of historic train stops into a readable light-and-shadow gradient. Once again, Zahner’s fabrication and prototyping expertise brought the concept to life, balancing poetry and precision.

“With Zahner, we can prototype light effects, study perforation gradients, and work iteratively to get every detail right,” said May. “That’s rare.”

Photo by Ramsey Attia, ARKO | © A. Zahner Company

Innovation as an Ongoing Dialogue

For HKS and Zahner, innovation doesn’t begin or end with a single project. It’s a shared practice. One that thrives on curiosity, openness, and the ability to see possibility where others see barriers.

“The work we’re doing together isn’t just about one stadium or sculpture,” said May. “It’s about building a relationship—and a methodology—that lets us explore, refine, and deliver something new every time.”