Applications

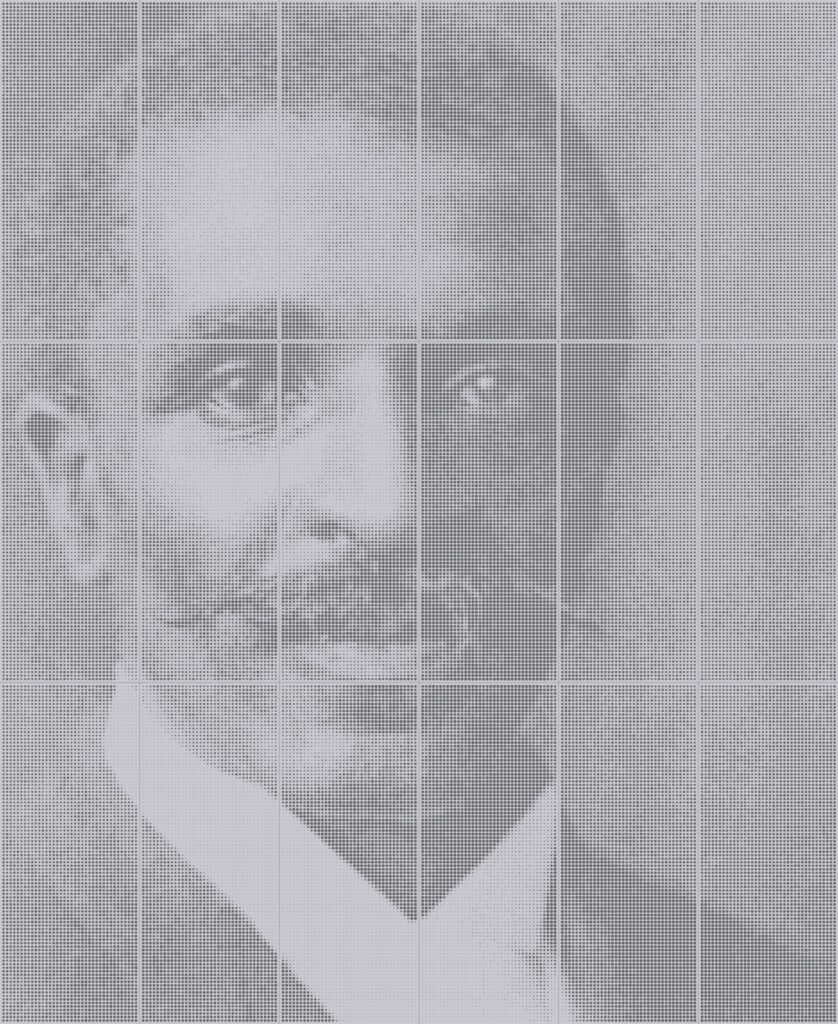

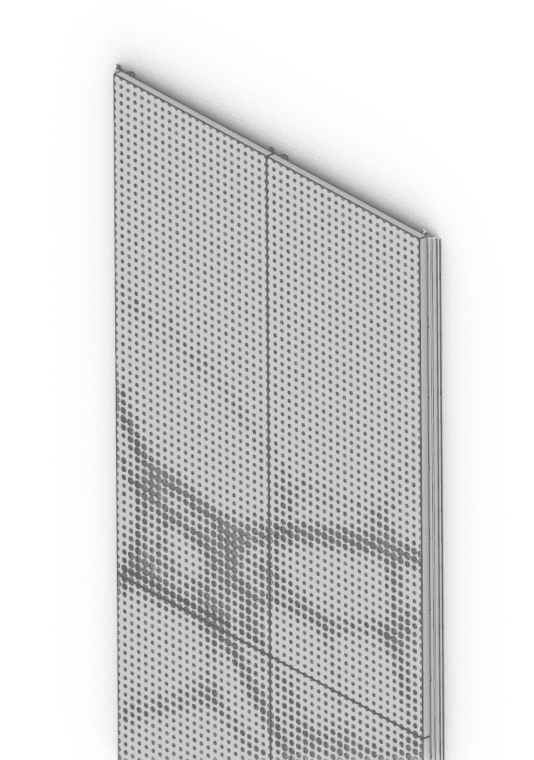

Perforated metal panels from Zahner can transform your project, whether that’s a 100 foot facade or an 8 foot partition. Our in-house manufacturing process creates perforated metal panel systems with continuous imagery across planar surfaces at high-precision tolerances.

Facade

Feature Wall

Screen

Perforated metal panels from Zahner can transform your project, whether that’s a 100 foot facade or an 8 foot partition. Our in-house manufacturing process creates perforated metal panel systems with continuous imagery across planar surfaces at high-precision tolerances.

Hear more about how perforated metal panels can be applied from Zahner’s Director of Sales, Eric Steele:

Features

Precision Manufacturing

Take advantage of generations of experience and powerful tools. Every perforated metal panel is custom made in our Kansas City and Dallas shops in the USA. Our shops are supported by 120 years of experience in metal fabrication and research.

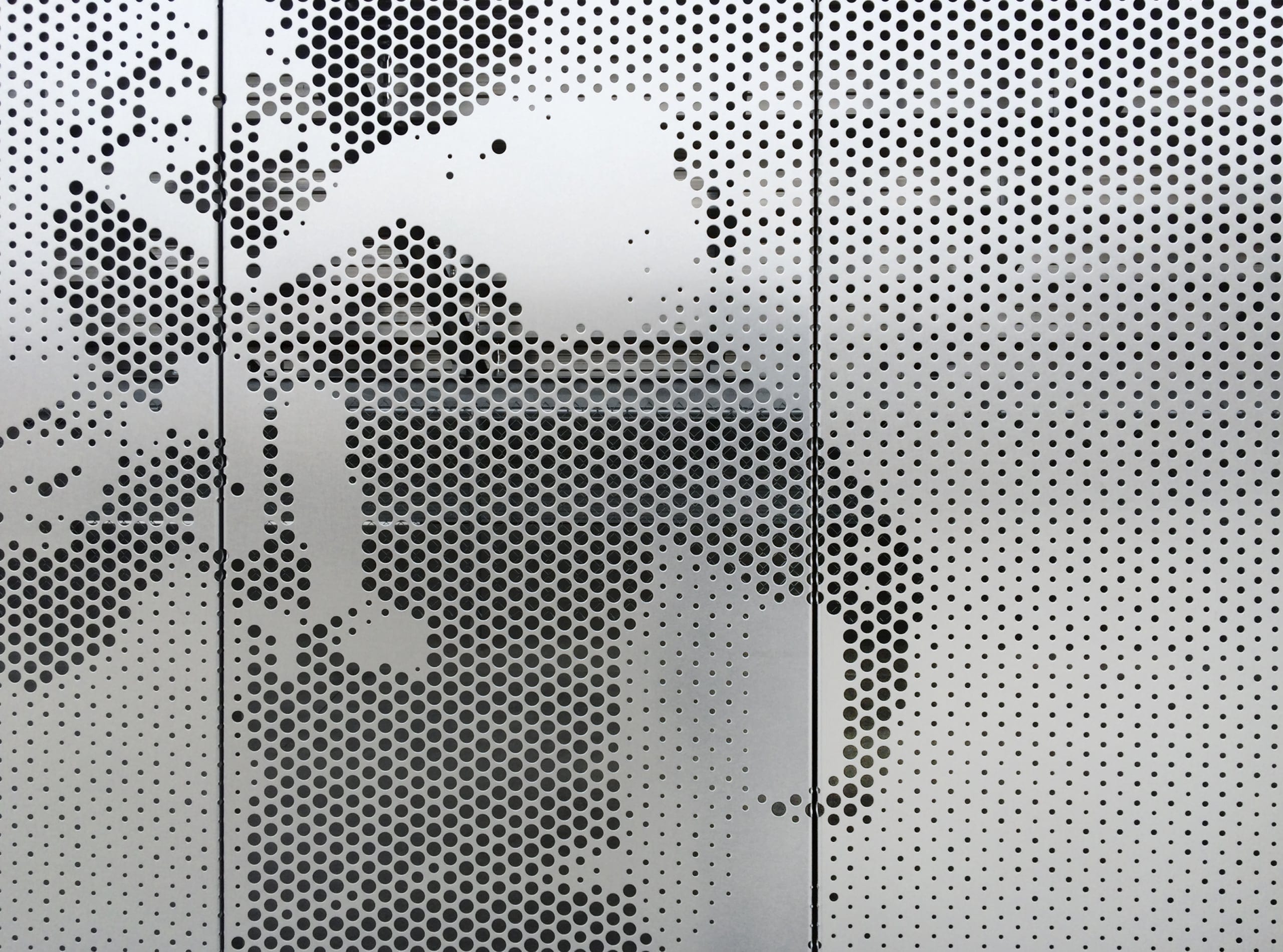

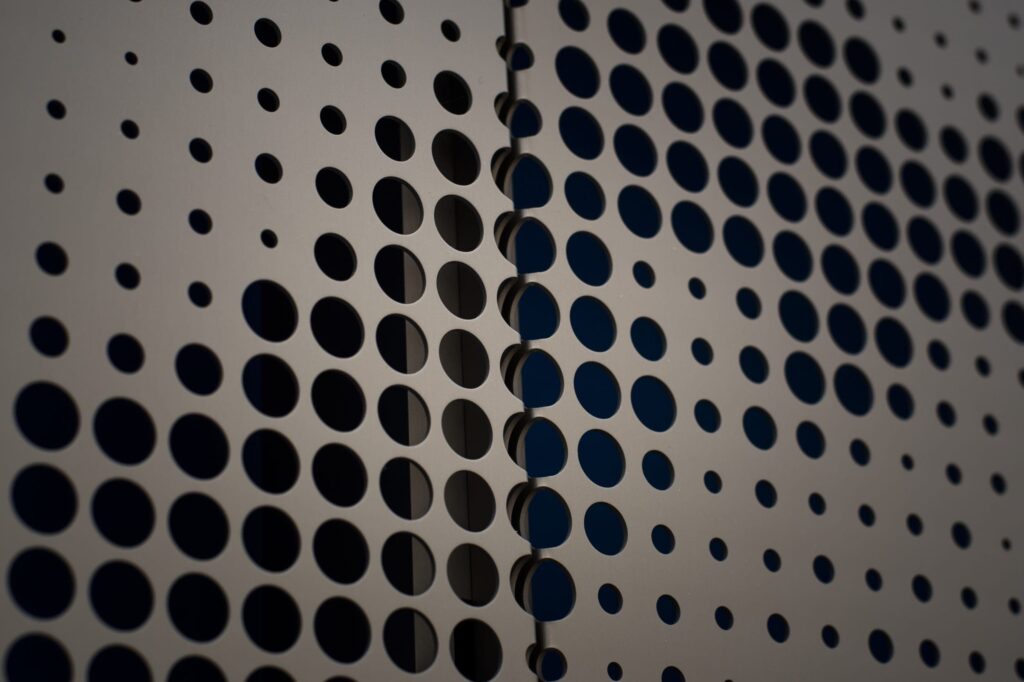

Seamless Transitions

Eliminate panel borders to create a seamless image. We have developed processes to create seamless imagery (Cross-Seam Perf™), by enabling perforations to continue across a folded seam or joint. Similar perforated metal panel systems often leave an unperforated border around each panel, obscuring imagery with a prominent panel grid. Zahner technology and craftsmanship ensure a high-impact display where boundaries and lines become undetectable at a distance.

Photo by Pierre Girad | ARKO

Photo by sarah Tesfai, Arko | © A. Zahner Company

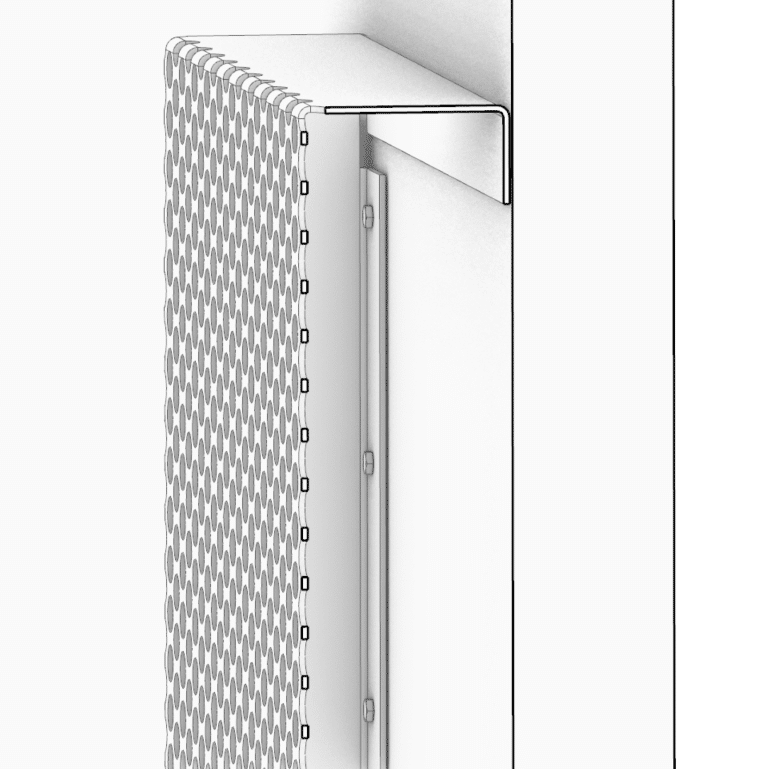

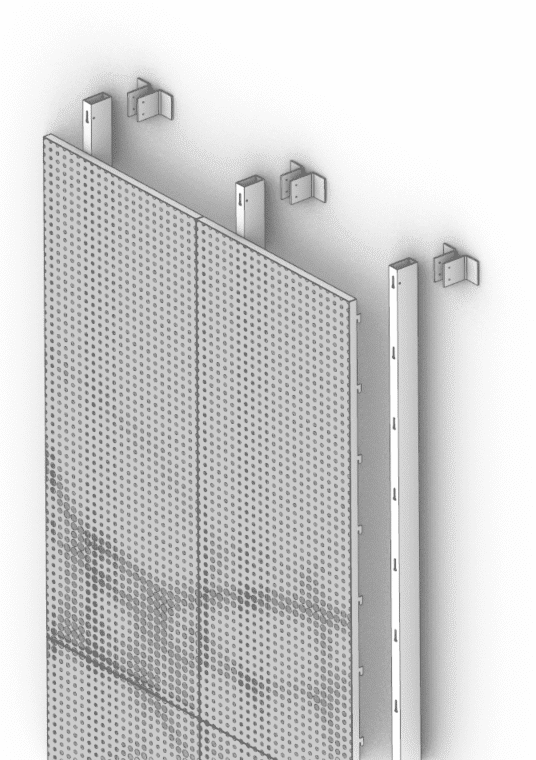

Simple Install

Install your perforated metal panels quickly and accurately without specialty tools. Panel attachment systems are designed to make accurate installation easy. The systems are developed in collaboration with licensed engineers for structural rigidity yet require no site welding, cutting, or adhesives.

Standard Configurations

Perforated metal panels are available in four standard configurations:

- Drop & Lock with mullion & anchor

- Drop & Lock with hat channel anchor

- Double Return long span system

- Double Return short span system

Drop & Lock™

Drop & Lock systems by Zahner use Inverted Seam technology to enable fast and sealant-free installation of perforated metal panels and other hardware for architectural systems. The systems use a two-part process for installation and include all of the hardware needed to hang the panel system. In addition to ease of install, Drop & Lock panels are also easy to remove and allow maintenance access to the space behind the panels.

Drop & Lock with mullion & anchor

Drop & Lock with hat channel

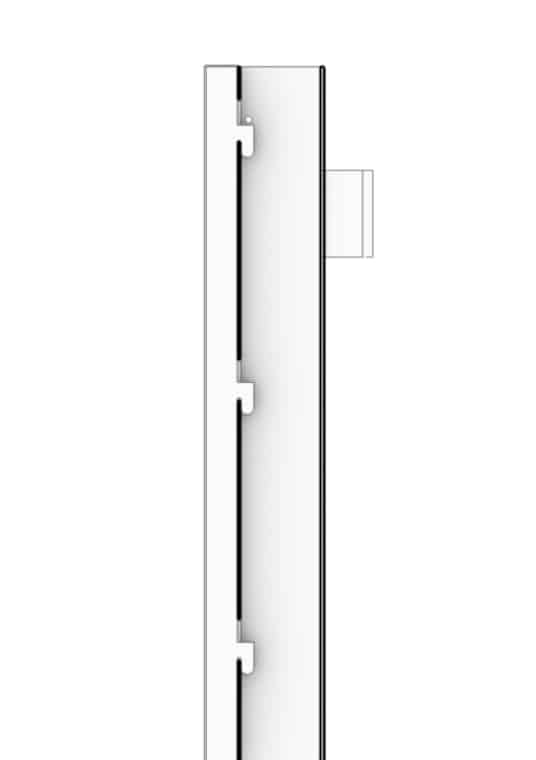

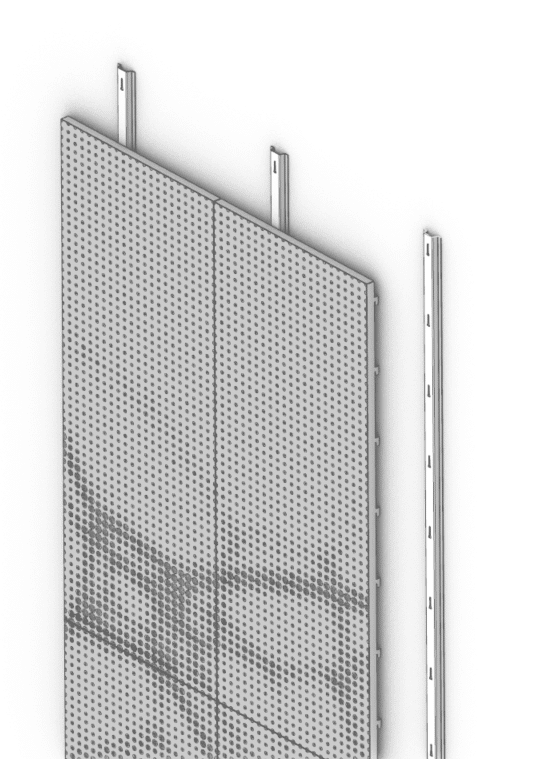

Double Return

Double Return is the most versatile perforated metal panel system. Panels are attached directly to the steel structures, or any other substructures designed and provided. With the Double Return system, the designer has the option to create the panel mount either horizontally or vertically.

There are two different variations of the Double Return system:

Long Span System

Long Span Panels have a broader flange to provide strength and rigidity to allow the panels to be fastened on the short edge only. Depending on the available substructure, panels can be installed in either vertical or horizontal orientation.

Short Span System

Short Span Panels have a thinner profile as the panels are fastened on the long edge. Depending on the available substructure, panels can be installed in either vertical or horizontal orientation. Double Return Short Span system is the most economical option.