Thermal Movement of Metal Surfaces

Thermal movement in architecture is the expansion and contraction of materials at an atomic level, based on temperature. In short, metal surfaces expand when the temperature rises. When the temperature dips, metal surfaces contract.

Thermal movement is one of several important aspects to understand when creating any architectural system. When designing a metal facade or roof, thermal movement ranks up there with joinery methods, constructibility, water shedding, and the behavior of light on the surface. These are some of the primary constraints for designing any large architectural system.

Thermal Movement Analysis of Metal Fabrications

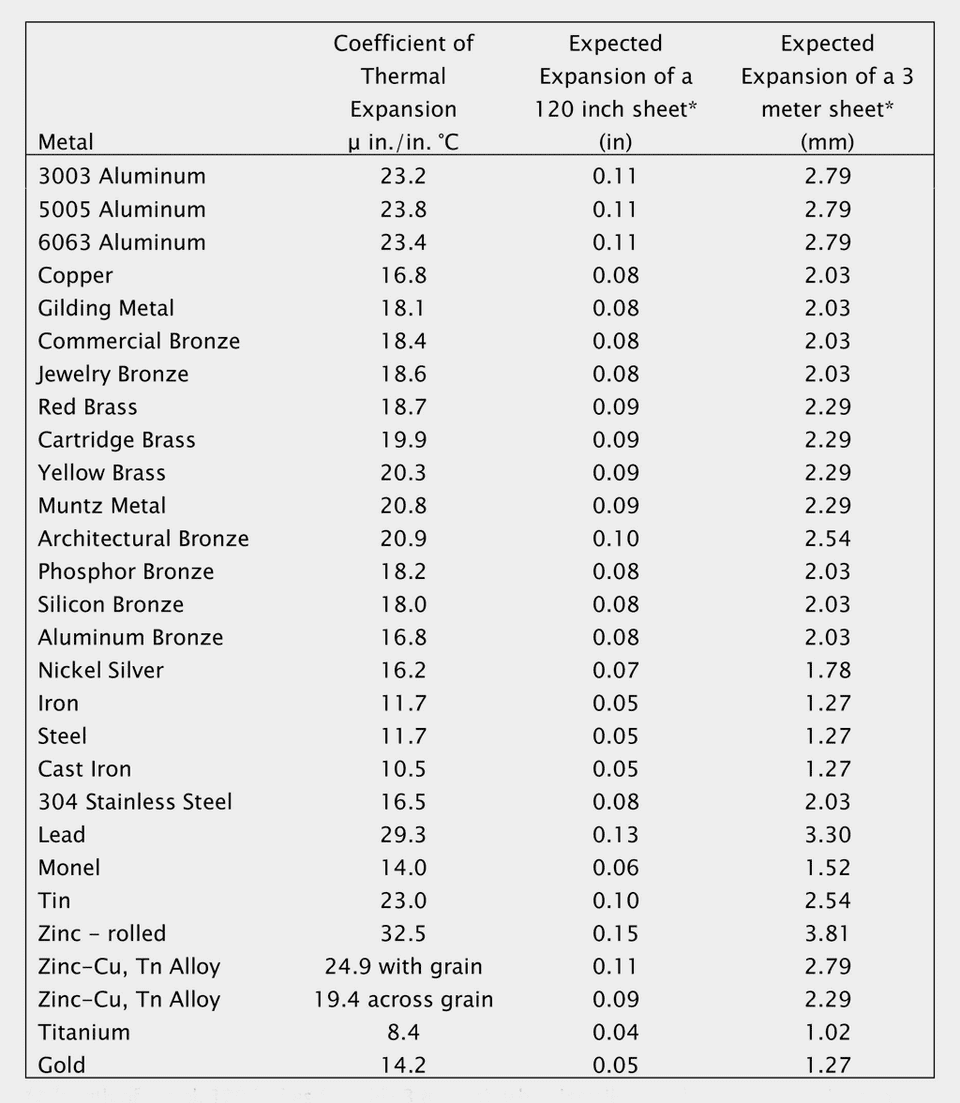

CHART © A. ZAHNER COMPANY.

Using this chart, you can easily determine how various metal systems will perform and what kind of tolerance your design should employ.

For instance, a length of metal, 120 inches (roughly 3 meters), when installed outdoors can experience a temperature differential of as much as 100°F (38°C). When this occurs, the metal will increase in length the amount indicated for that metal. If the metal is to be subjected to a higher temperature range, then you must allow for the additional expansion.

Diamond Patterns: Thermal Movement

In standard facade designs, the diamond pattern is inherently strong. By using interlocking plates of the surrounding panels, the load is taken out at the seam. Correctly installed, diamond pattern systems have shown centuries of performance due to the inherent strength and the reduction of stress maintained by the overlapping pattern.

Dimensional changes of the panel elements caused by thermal effects are handled efficiently with the diamond pattern. The top edges of each panel are fixed, usually with clips; and the bottom edges interlock into the single-lock seam along the top edge of the row of panels below. Expansion and contraction are away and toward the clips, effectively sliding over the single lock of the panel element below.

DIAGRAM © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

Thermal movement is one of the big considerations in developing a metal panel system which lays flat and doesn’t buckle or oil can. Other considerations include metal thickness (and thus its tendency to bend or bow), reflectivity (highly reflective surfaces reveal more discrepancies in flatness), and wind forces.

Each of these issues can be resolved through careful planning and proper detailing. Learn more about how to develop a high-quality metal system by contacting an expert at Zahner.

References

- Zahner, L. Architectural Metal Surfaces. New York: John Wiley, 2004.

- Zahner, L. Architectural Metals: A Guide to the Selection, Specification and Performance. New York: John Wiley, 1995.