Festival of Arts

Festival of Arts and Pageant of the Masters, Laguna Beach

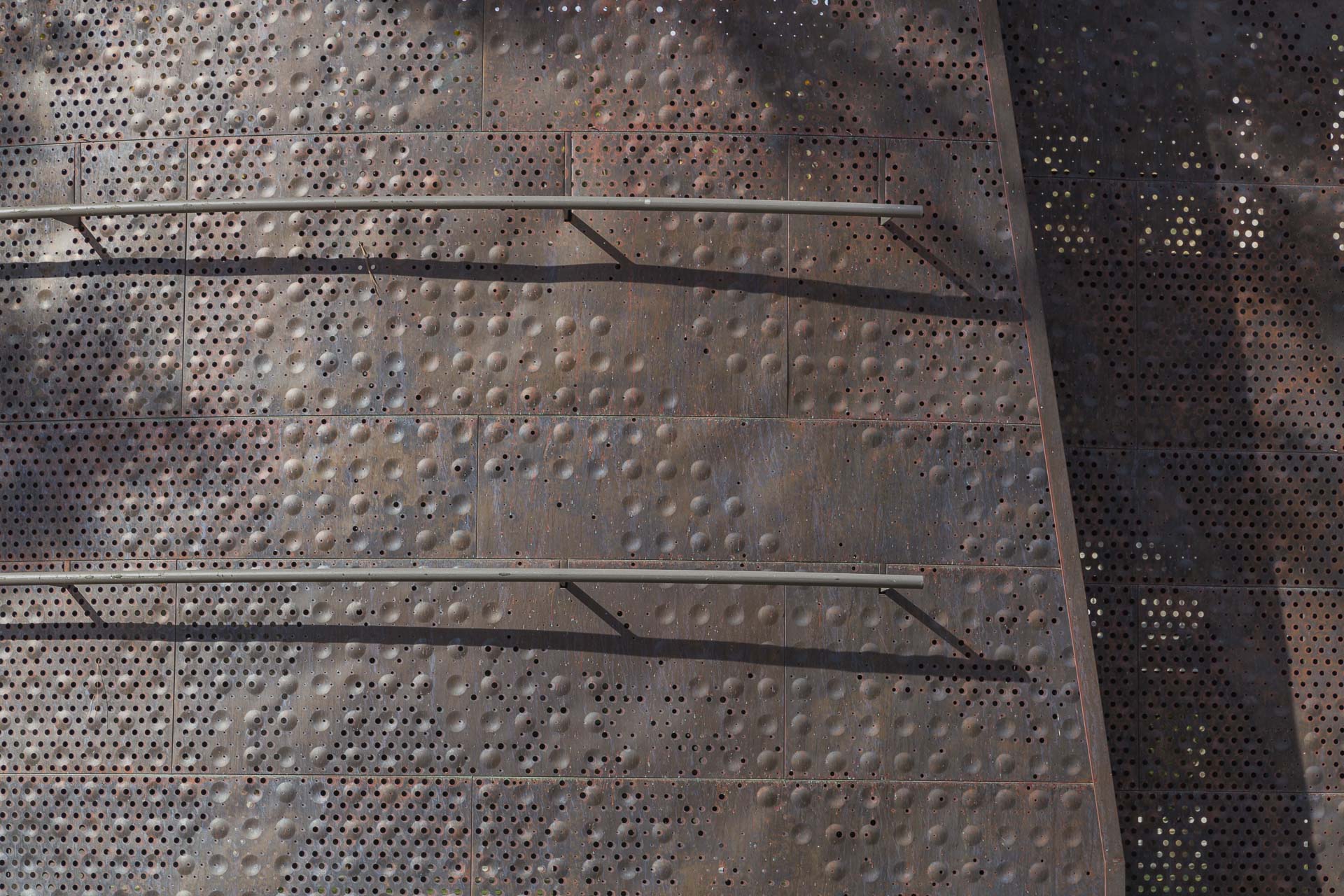

Combining both natural and built elements from the surrounding environment, the Festival of Arts renovations link both the City of Laguna Beach with its surrounding canyon landscape. Zahner’s scope consisted of fabricating a series of five stand-alone wall sections, the tallest of which rises to nearly 20’. These act as both a decorative feature wall and a place-holder for signage regarding various events and exhibitions.

The existing concrete signage wall was demolished as part of the proposed renovation. Bauer Architects sought to reimagine the wall as art. They started with the image of tree branches, a link to the forested setting using the words of the philosopher Seneca, “All art is but an imitation of nature”.

For the perforations, a standard circular punch shape was used to create imagery of trees on the form’s copper surface. These shapes were then cut from the metal using a punch. When assembled in unison, the panels read as an entire image. To create additional texture and add rigidity to the panels, a series of embossed and debossed bumps were applied to the surface.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Growing a Stable Patina on Architectural Copper

The architects wanted to use a natural material with an aged look. Zahner’s Dirty Penny patinated copper was selected as the base material. This oxidized copper material was developed by Zahner to expedite the natural weathering process of copper. Rather than taking years to develop a rich, dark patina, the Dirty Penny process results in a stable patinated surface using a rapid chemical-based treatment. The panels for Festival of Arts were pre-patinated and shipped directly to the jobsite for installation.

The unsealed patinated panels will continue to age with time. The metal’s surface acts as a living protective barrier, similar to the way moss grows on stone. Unlike paint or anodization, which will deteriorate with time, the custom copper patina will continue to grow stronger as the surface oxidizes.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Manufacturing Accurately-Curved Architectural Forms

Creating the curvature for the panels proved to be a unique challenge. Some of the walls were derived from a single radius, while other sections included more than one radius in a single wall. All of these were tangent to one another. Due to the embossed and debossed bump pattern, the usual method of processing the entire sheet through a roll former could not be used. This compression would damage the bumps. Zahner’s solution was to crimp roll the top and bottom legs of each panel.

Crimp rolling the edges gave the sheets a gentle curve, but the process is not entirely precise. So to increase precision, Zahner also created a series of aluminum templates at the desired radius. Zahner was able to match the copper panels to the aluminum templates during the crimping process, resulting in a highly accurate architectural form.

The resulting geometry matches identically to the each of the radii provided in the architect’s model.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Festival of Arts in Laguna Beach, California.

PHOTO © A. ZAHNER COMPANY.

Simplifying the Concealed Attachments

Copper rolled angles were used as attachment hardware on the backs of each panel and fastened to existing mullions. In order to fit the curvature, these angles were also stretched to the appropriate radius. Coordination of fasteners to the copper rolled angles became key.

To disguise fasteners, Zahner assisted with coordinating the location for a series of aluminum “hats” on the mullions. Each piece of hat hardware lines up with a perforated hole. Fasteners were run through the perforations, to the back hardware. This allows for panels to be removed with ease, so that signage could be easily installed, and maintenance remains uncomplicated.

Designing concealed hardware is one of the advantages of using Zahner’s engineering and design team for projects like this. Contact Zahner to see what kinds of assistance we can provide for your project, or learn about how you can get your team started early with Zahner using Design Assist.

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

© Fedora Hat Photography

© Fedora Hat Photography Photo by Andre Sigur | ARKO

Photo by Andre Sigur | ARKO

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.