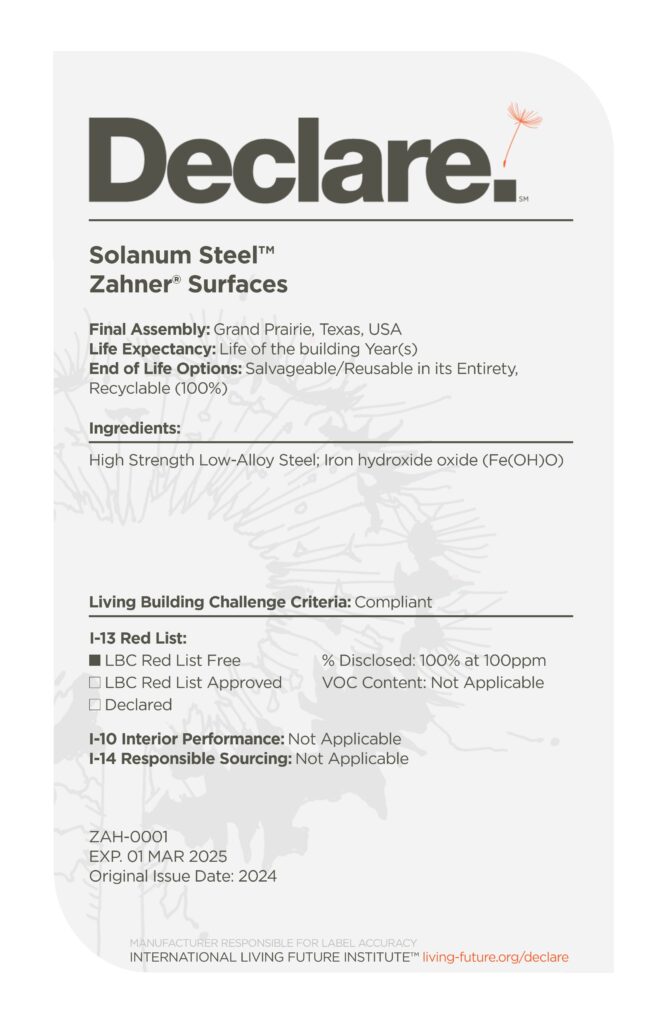

Declare is a transparency initiative by the International Living Future Institute, providing an “ingredients” label for building products that enables design and build teams to make informed choices.

File Type:

jpg

File Size:

212 KB