Inverted Seam™

Roof Cladding System

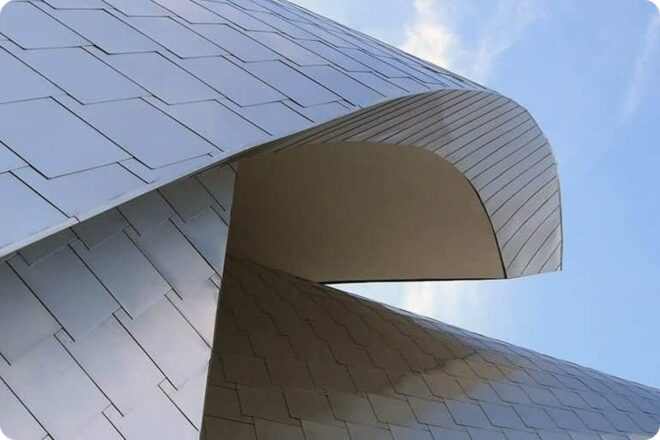

Inverted Seam is a roof system that provides designers with a smooth uniform metal surface on for a variety of roof applications including low-pitch surfaces. The system provides a powerful method for controlling precipitation through subsurface channels with no visible fasteners.

Inverted Seam Inspiration.

Inverted Seam Inspiration.

Finishes

Finishes

These Zahner Surface are compatible with Inverted Seam.

Request a Sample

About Inverted Seam

About Inverted Seam

Inverted Seam was developed by Zahner as a solution to create the smoothest, most uniform cladding system with powerful moisture control. As a roof system, Inverted Seam is free of upstanding ribs and seams that define typical metal roof surfaces. It is also free of face-fasteners. All of the attachment hardware is based on internal interlocking hardware.

The highly flexible system is often used to prevent moisture build-up on low-pitch or nearly flat roofs. When precipitation strikes the surface of the roof, the moisture is contained on the surface or confined within a concealed guttering system. This series of channels runs the course of the entire roof, to be diverted into drainage or water collection systems.

The system is fully engineered to control moisture with metal. Inverted Seam systems are not dependent on seals or membranes to keep moisture out. It incorporates secondary and tertiary water deterrent mechanisms within the cavity spaces below the metal surface.

The Inverted Seam system provides a number of features and benefits:

Benefits of Inverted Seam:

Secondary and tertiary water deterrence

Aluminum, steel, stainless steel, brass surfaces

Guaranteed performance

Fully engineered surface

Low slope

No upstanding ribs

Can run perpendicular to water flow

Highly adaptable

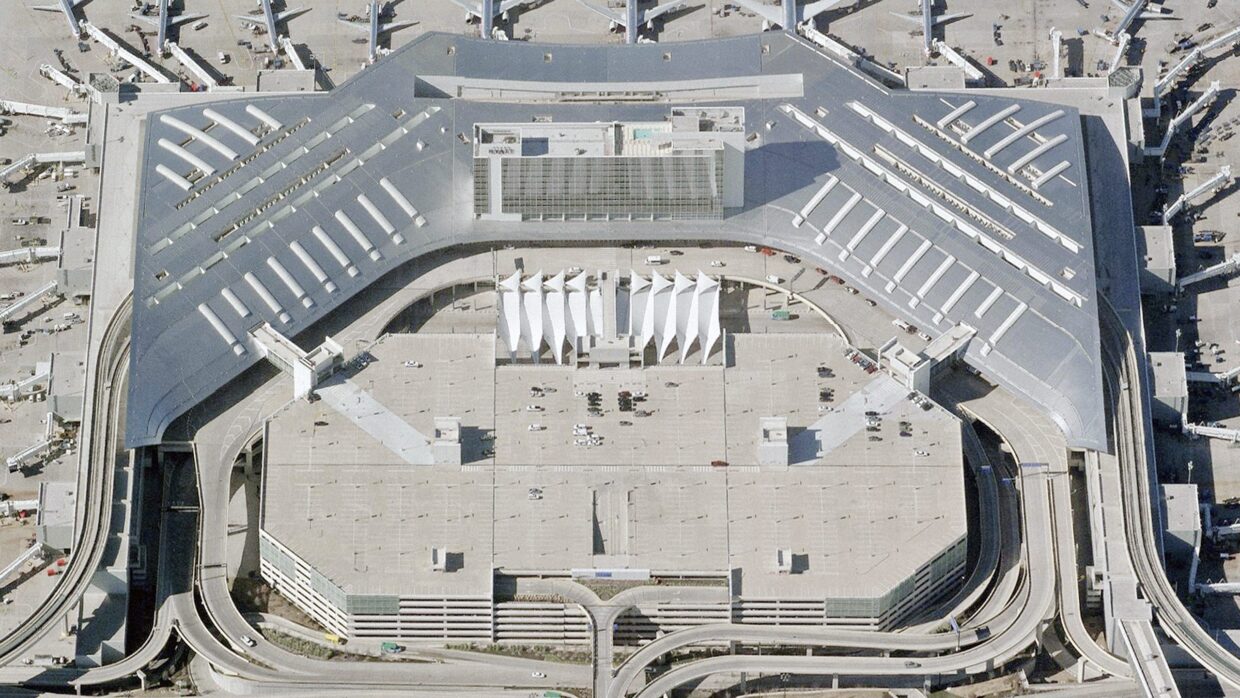

Inverted Seam Projects

Inverted Seam Projects

About Products & Systems

About Products & Systems

Learn how to purchase and specify Zahner products and systems.

Zahner Standard Products are ready-to-order solutions.

From Zahner’s signature metal Surfaces to the Moda modular wall panel system, Standard Products are cost-effective options to bring extraordinary impact, material quality, and performance to projects of any size or any budget.

Zahner Versatile Systems are pre-engineered solutions that are ready to specify.

They are the perfect way to get ready-to-install Zahner Surfaces without the time and costs of a custom-engineered solution.

Versatile Systems can be adapted to fit your project requirements, typically offering multiple options for panel sizes, shapes, and joint layouts.

The Zahner Custom Solutions team team drives project innovation through collaboration with designers, architects, and artists.

Custom Solutions leverage Zahner’s full capabilities, services from pre-design to installation, and even R&D, all aligned to deliver on your most ambitious vision.

Take the Next Step with Inverted Seam

Build the Incredible with Inverted Seam.

Bring the beauty and performance of Zahner’s metal surfaces to your project with Inverted Seam.