Solanum Steel is a pre-oxidized weathering steel (Corten) surface developed by Zahner. The surface is produced by accelerating the natural weathering process and stabilizing the result. Solanum Steel provides artists, architects, and designers with a range of resonant tones on an enduring surface.

One of the well-recognized challenges of using steel in architecture is its propensity for the material to rust or oxidize. Although many appreciate the warm hues of weathering steel, nobody likes it when the material’s color bleeds onto other surfaces. The Zahner preweathered steel process reduces the material’s tendency to stain adjacent surfaces.

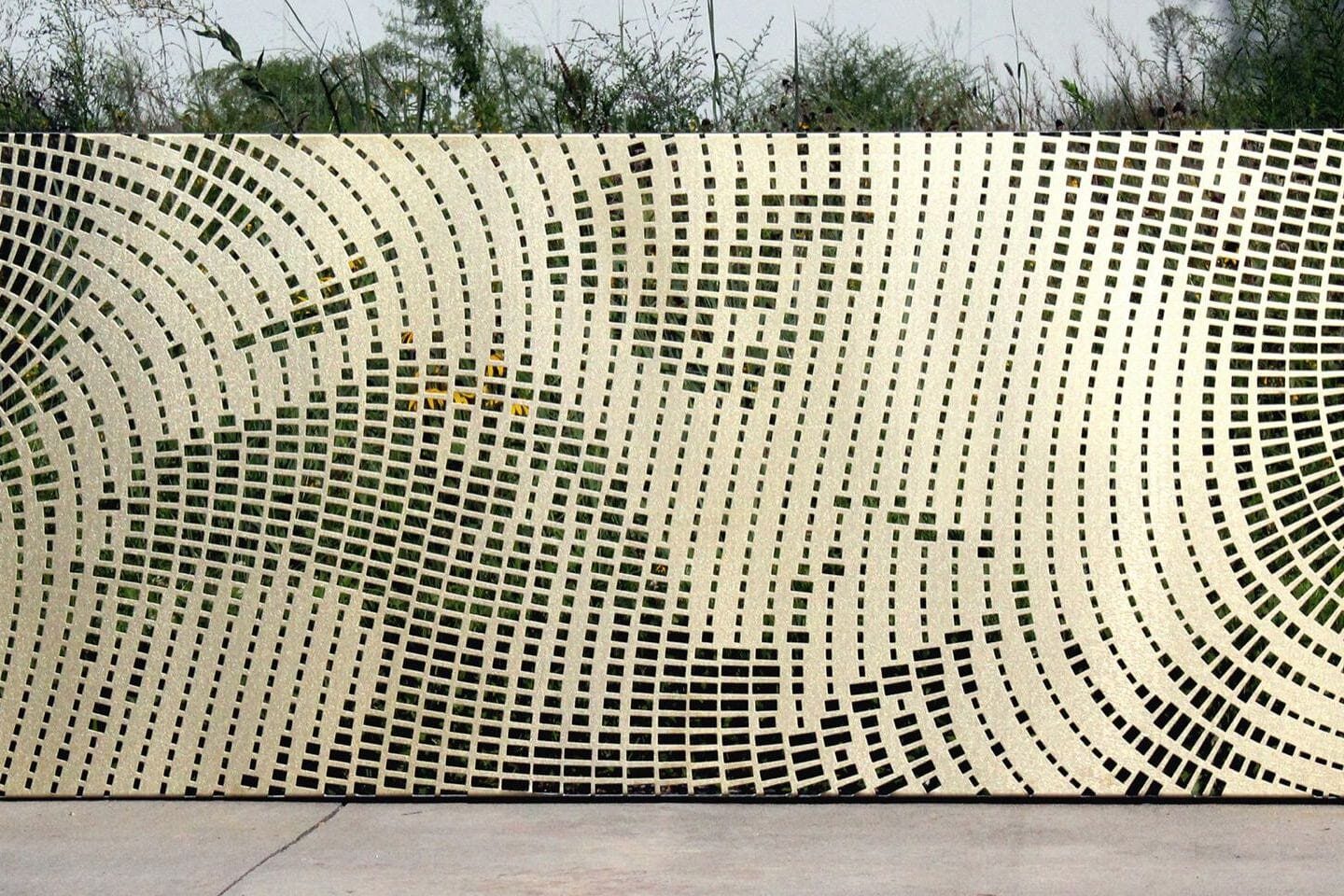

Close-up of Solanum Steel sheet material.

Photo © A. Zahner Company

Fabrication: Corten Steel or Solanum Steel

Solanum Steel, weathering steel, copper-bearing steel, and COR-TEN (Corten) areall names for a durable subset of steel alloys (A-242 and A-588). These steel alloys offer long-term endurance in exterior conditions. Instead of corroding away, as these materials surfaces oxidize, the oxidized layer becomes a protective layer.

The issue with fabricators who use standard corten alloys is that it takes a few years of exterior exposure before the material’s rust condition stabilizes. During this process, the material will bleed.

Solanum Steel resolves this challenge by bringing the natural weathering steel alloy into an insoluble and stable state. This preweathered surface is accelerated in a dedicated Zahner facility for producing sheets and custom fabricated corten forms in Solanum Steel.

How Solanum Steel is Manufactured

The typical alloy used in Solanum Steel is ASTM A-588, developed as an advancement over the original alloy used in COR-TEN, a trademark of U.S. Steel. Since the material was first made public, it has been utilized by architects on countless projects.

The Solanum Steel process begins at the raw steel ingot. Zahner has a close relationship with both the steel mill and the rolling mill, and can influence the quality of the surface long before the raw sheet arrives. This ensures that the material derives from specific alloying components and that the base raw material is cast to exacting specifications.

Then, the ingot is processed by Zahner’s rolling mill partner, whose finesse with steel ensures that the surface is properly treated to avoid streaks, rings, and discolorations.

Zahner patina engineers inspect each and every plate surface. The bare Solanum Steel is then cleaned and prepared to eliminate oxides and contaminants. If this step is not carefully followed the finish will not hold up.

Once properly prepared, Zahner force the surface to an initial ferric oxide. This finish is slightly orange in color and is characterized by a crusty texture.

An orange patina is not as permanent as a dark patina. A patinated steel showing yellow and light orange colors will rub off and continue to bleed and stain adjoining surfaces, unless sealed with a durable coating.

Solanum Steel seen under a microscope. Note the flaky appearance of the typical weathering steel patina.

Photo © A. Zahner Company

Zahner allows the orange-toned oxide to grow to a point before removing the majority of it from the surface. The surface is then exposed to a proprietary bath with specific atmospheric conditions to develop a hydrated oxide form.

At this stage, the steel surface becomes insoluble. The material is then arrested with a final bath that inhibits and slows oxidation to a standstill.

Sealing Solanum Steel

In some circumstances, the Solanum Steel material can be sealed. This is often desired for trafficked environments where people will touch the surface.

For interior applications of Solanum Steel, the material can be sealed with a clear coating to provide a softer touch. However, for exterior applications, it is recommended to leave the material unsealed.