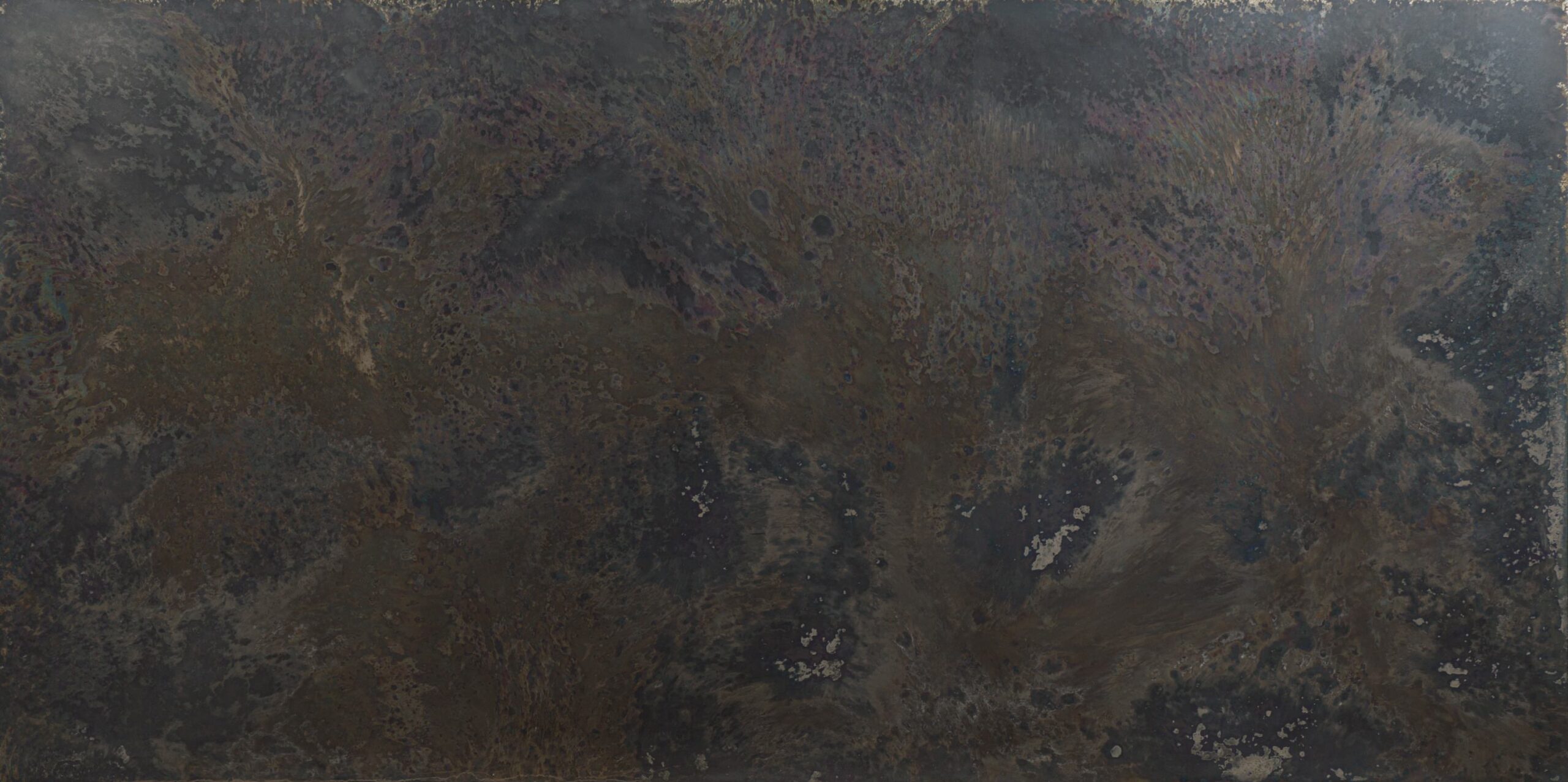

Oscura is a rich, blackened steel patina designed for interior applications. Its activated steel surfaces create a unique, mottled aesthetic that varies with each sheet, offering a distinctive artistic ambiance. Sealed with a protective clear coat, Oscura resists rust and scratches caused by the interior environment, ensuring durability and elegance. This proprietary finish is ideal for feature walls, lobbies, accents, and other architectural elements.

Each Oscura sheet is one of a kind, with high variability in color patterning from sheet to sheet.

Crafted with proprietary processes, Oscura is not only a striking material but also an environmentally conscious choice. Produced in our EPA-compliant facility, its creation minimizes waste through sustainable practices. Oscura’s rich black and gray hues, achieved through specialized heating and sealing techniques, provide warmth and texture that complement diverse design palettes. Oscura is a long-lasting, stunning addition to any interior space.

Oscura Blackened Steel Manufacturing, Properties, and Applications

Oscura is more than just a beautiful material. It’s a responsible choice, made using environmentally friendly manufacturing practices in our award-winning, EPA-compliant facility. We take pride in capturing and recycling all residual bath minerals and compounds to mitigate our environmental impact.

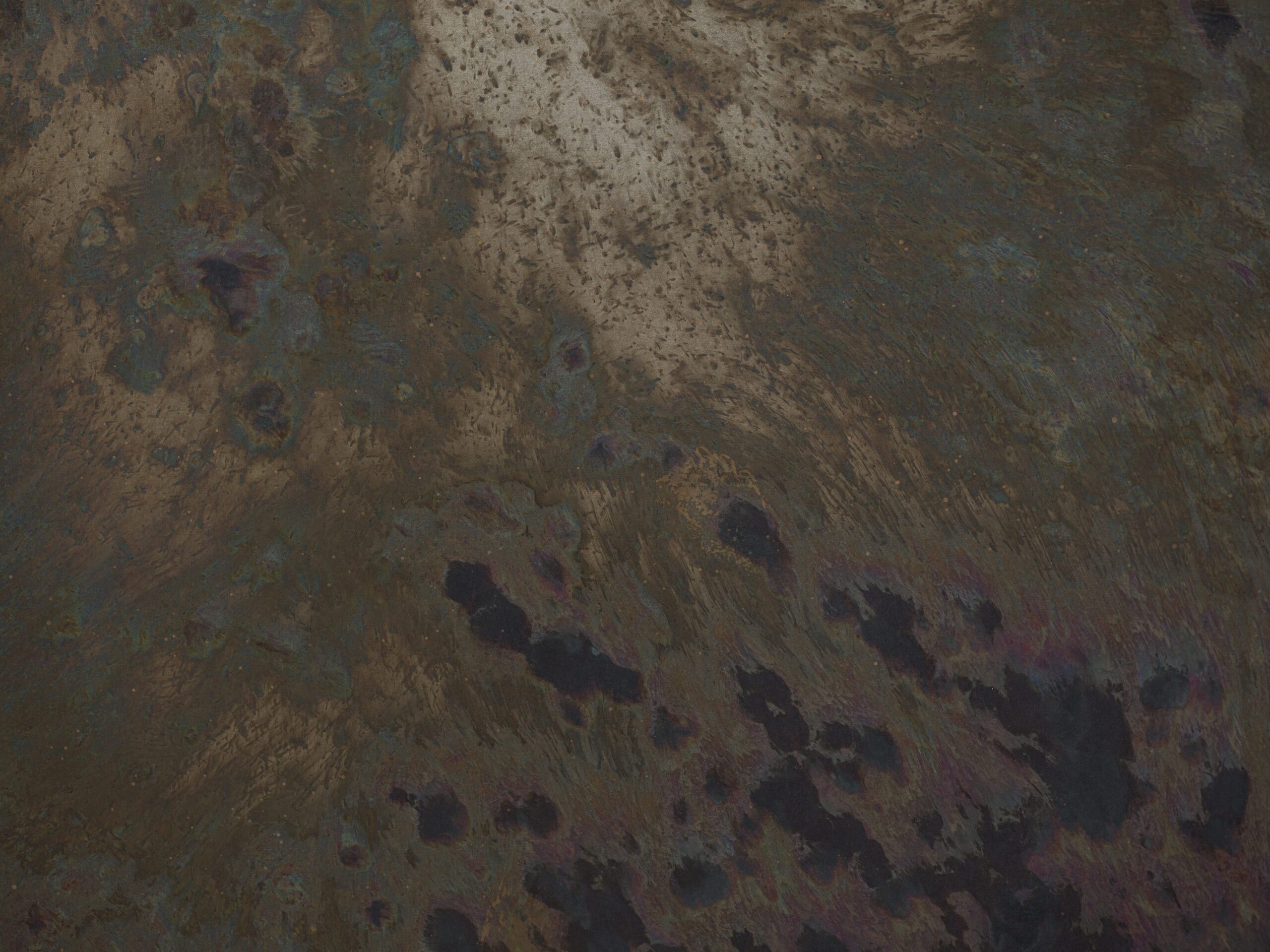

Close-up of Oscura Blackened Steel sheet material.

Photo © A. Zahner Company

The versatility of Oscura is unmatched. The dark blues of the steel, combined with the heavier carbon alloys of cast iron, create a tapestry of black and gray hues that can complement a wide range of materials and colors. From dark brown to black, the color of Oscura can vary depending on the intensity of the oxide on the surface of the steel. While the oxides produced by our proprietary alkali method are beautiful, they are also delicate and prone to abrasion. That’s why we recommend and regularly reapply appropriate protective coatings to ensure its long-lasting beauty.

Patination of Oscura Blackened Steel

The iron alloys are not commonly used in the uncoated state. Left to nature’s devices, these alloys will develop a rust oxide which will eventually corrode in entirety. The natural color of the iron alloys, when cleaned of scale and mill oil, is a dark blue-gray.

The steels have a dark blue-gray color, while the heavier carbon alloys of cast iron are almost black. Cast iron has a dark carbon-gray surface, which will weather to black. The wrought iron forms are dark blue-gray in tone. Heating blackens the surface, and subsequent shaping drives the dark tones into the surface. Wrought iron is almost always coated with a thick paint to inhibit corrosion.

Oscura Blackened Steel can be blackened or given colors ranging from dark brown to black. One such method to achieve these tones is by dipping it in a heated chemical bath. This process can develop a deep black oxide over the surface of the steel. Oxides produced by this alkali method are weak and prone to abrasion if not protected with waxes or oils. Protection against corrosion is enhanced slightly, but the base metal characteristics may cause a blackened finish on steel to fail if not continuously maintained in an indoor environment.