Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

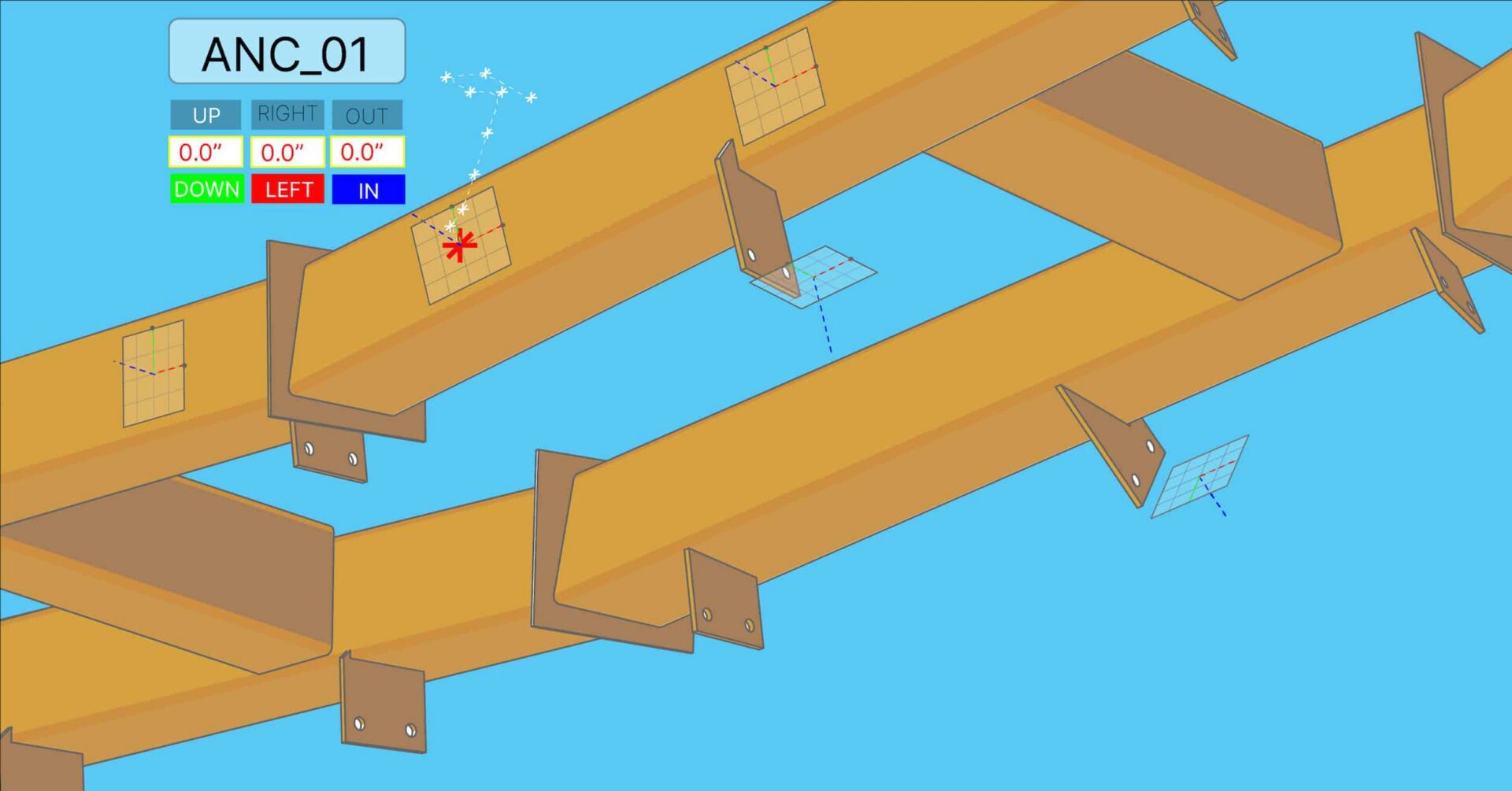

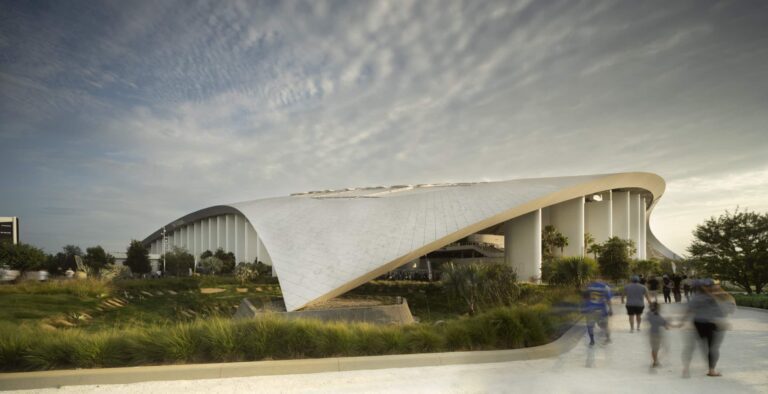

Over the last 30 years Zahner has delivered hundreds of the world’s most iconic and challenging buildings. Zahner often develops software tools to analyze survey (or pointcloud) information and as-built conditions, but these computational patches only speed Zahner’s analysis portion and don’t address larger multi-trade coordination. To address this problem, the Zahner Labs team has created SurveyLink—a real-time data link between as-designed 3D models and as-built data collected in the field (Figure 1).

SurveyLink offers the same transformative potential to field crews that 3D modeling brought to design professionals in the office. The streamlined delivery method improves productivity by eliminating unnecessary remobilization of field crews and reduces the lengthy review periods typically associated with construction administration.

Key Benefits:

- Improved quality

- Lower construction costs

- Streamlined conflict resolution

- Safer job sites

- Expedited lean construction

As a project moves from the office to the job site, the tools for design and coordination diminish in sophistication and accessibility (Figure 2). In the design phase, architects and design engineers wield a suite of tools for computational modeling, finite element analysis (FEA), simulation, data sharing and 3D computer-aided design (CAD) visualization. Whereas when construction begins their counterparts on the job site operate with 2D documents, tape measures, levels, string, and occasionally surveying tools such as a Total Station.

When a project is complex and changes from one inch to the next, 2D documents are not comprehensive, resulting in much of the construction left up to interpretation. This leads to discrepancies between the as-designed 3D model and the as-built physical construction. This is further complicated when the design engineers responsible are located in offices geographically far from the construction site (Figure 3).

Problems with the status quo

Current communication methods such as emailing PDFs, spreadsheets, verbal descriptions, mobile phone photos, text messages and hand-drawn sketches are insufficient in conveying a complete picture of onsite conditions.

This separation of parties has a two-pronged effect: design engineers and architects in the office don’t have eyes on what is being done at the job site and the field crew doesn’t have a full picture of what they are producing. This results in review and revise iterative “loops” and expensive rework. The industry needs a new approach.

CLICK TO JOIN COLLABORATIVE SURVEYLINK SESSION

3D models accessible from anywhere

Signup and we’ll show you how it all works (no surveying knowledge required).

With SurveyLink, on-site survey crews upload captured coordination point data to a collaborative model. SurveyLink provides cloud storage and collaborative CAD/BIM visualizations. Connected users can instantly access and see positional deviations between the as-designed and as-built coordination points in 3D using a lightweight web application.

As newly shot survey data is uploaded, deviation values are automatically updated on the model and available to everyone involved in the project. PDF reports and mobile phone photos are replaced by 3D visualizations that can be interacted with simultaneously by field crews on their mobile device and design engineers, or project managers, on whatever device they choose.

Mobile-accessible cloud storage allows survey crews working on site to access and upload new data at any time, solving the communication issues that arise from geographically distributed teams. Field crews are seeing the same three-dimensional data on their mobile devices that the design engineers are viewing in the office. SurveyLink is in essence a tool that eliminates fragmented communication between the office and job site—in real time, in 3D, on mobile devices, and in the browser.

Go Further with SurveyLink

Have a question about SurveyLink — or want to work with Zahner and SurveyLink? The Zahner Labs team can help. Just fill out the form and let’s collaborate.