Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

Sparking the Inspiration

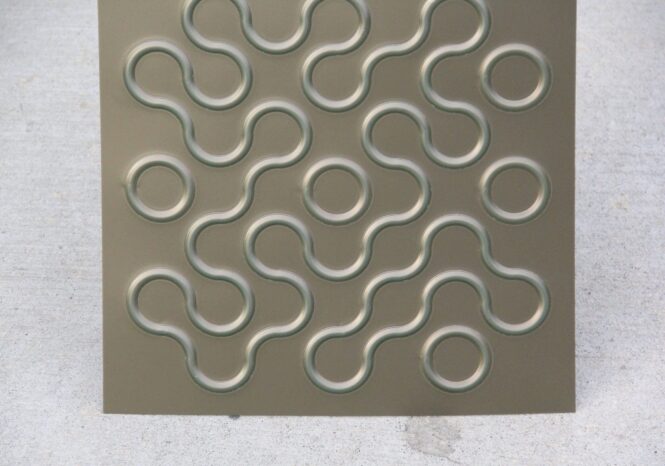

Through our Zahner Labs process documentation and experimentation, we’ve created this Bead Rolling Inspiration Guide. It contains a variety of panel designs using our CNC punch to demonstrate just how versatile a tool it is (and hopefully spark some ideas for your next project).

The Role

Sheet metal is available in a variety of thicknesses, but even the thickest are relatively “floppy” until formed into a shape. Like a piece of paper, sheet metals can be formed, folded, and cut into many different shapes.

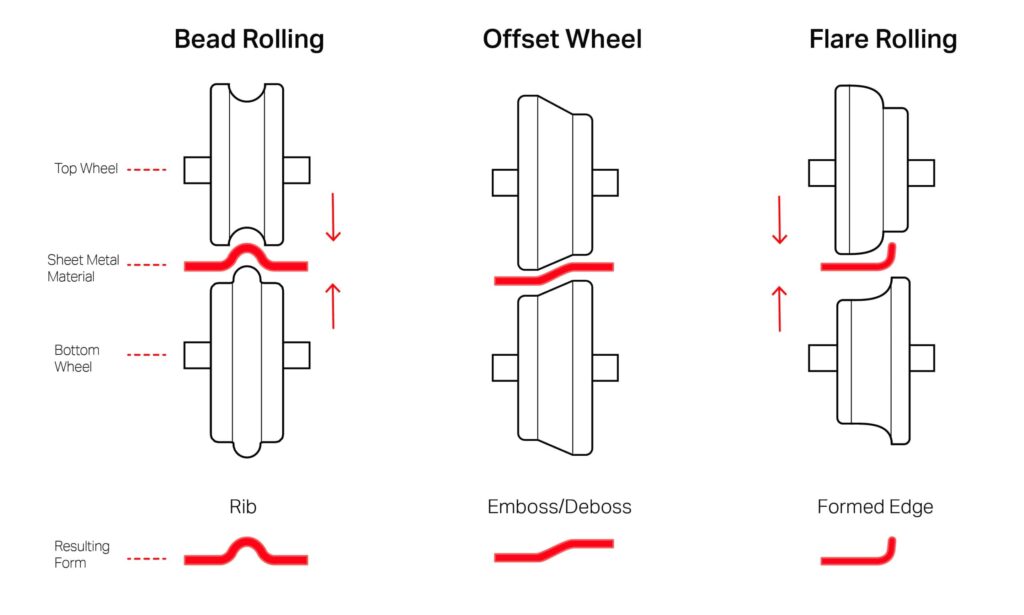

Adding to a sheet’s cross section stiffens the sheet and helps maintain flatness. Bead Rolling is a ‘wheeling’ technique used to selectively emboss/deboss sheet materials to increase part rigidity. The result is a panel with material properties that are visualized through geometry – the more shape, the stronger the panel becomes.

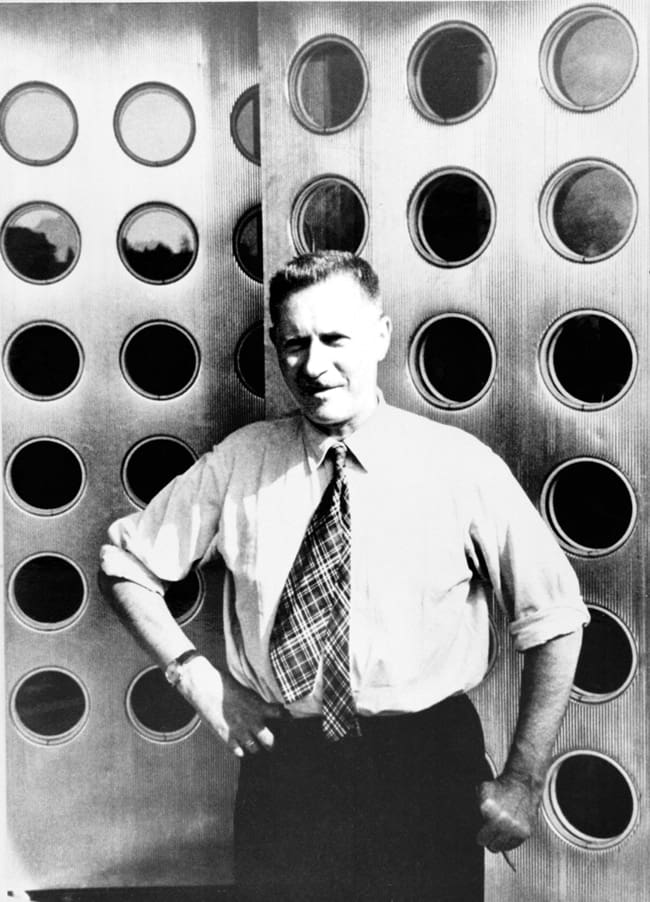

A rich tradition of wheel forming parts to increase their stiffness exists, from Jean Prouve’s Tropical House details to aircraft wings. The aesthetic of wheeled parts resembles that of stamped parts, a mass production technique typically only reachable by high volumes (due to prohibitively high tooling costs). Wheeling, however, offers designers the opportunity to explore formed sheet metal parts without the costs typically associated with stamping and other metal forming techniques.

Functional Beauty – Illustrations, Diagrams, Photos

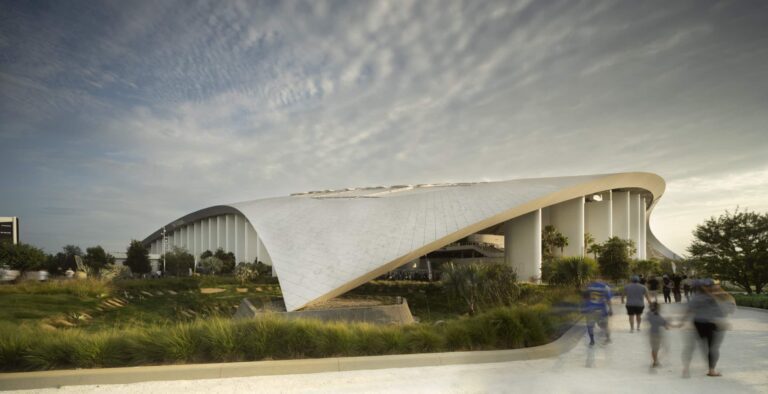

The utility of wheel forming as a panel stiffening technique can be used by designers as a design feature—expressing panel engineering—a blend of engineering requirements and material effect.

Bead rolled panel in color shifting coil coated aluminum

Embossed panel with offset wheel in color shifting coil coated aluminum

Let’s Roll

Got a question about bead rolling? Or maybe you have an idea and you’d like an expert opinion on the feasibility. The Zahner Labs team can help. Just fill out the form and let’s collaborate to bring your vision to life.