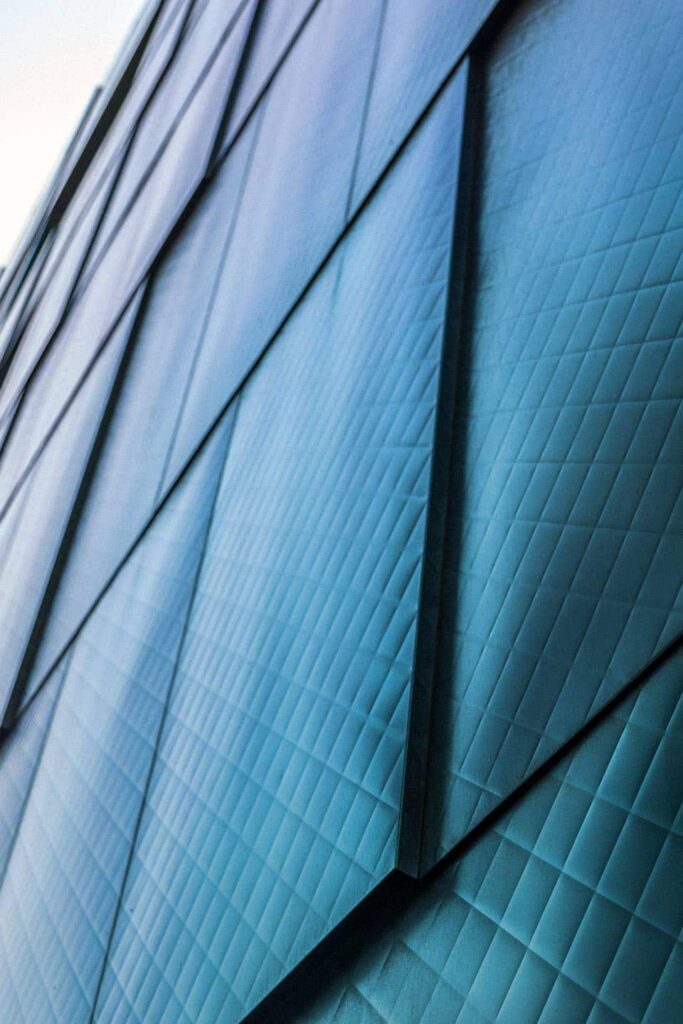

Metal embossing has been used in a wide variety of projects to transform the material aesthetic while providing added rigidity at a typical cost. A simple bump shape repeated across the surface of a metal panel can transform a standard panel system into something worth noticing, while also providing performance benefits. From custom embossed shapes to textured surfaces, selective embossing provides a great range of potential.

In addition to providing unique textures for metal, custom metal embossing rigidizes a surface. There are various methods to develop a uniform planar surface in metal. Folding the edges is one way to inbue panels with rigidity. Another way is to simply increase the thickness of the sheet metal into a more rigid plate form. Using an ACM panel also works, although it has an ecological downside.

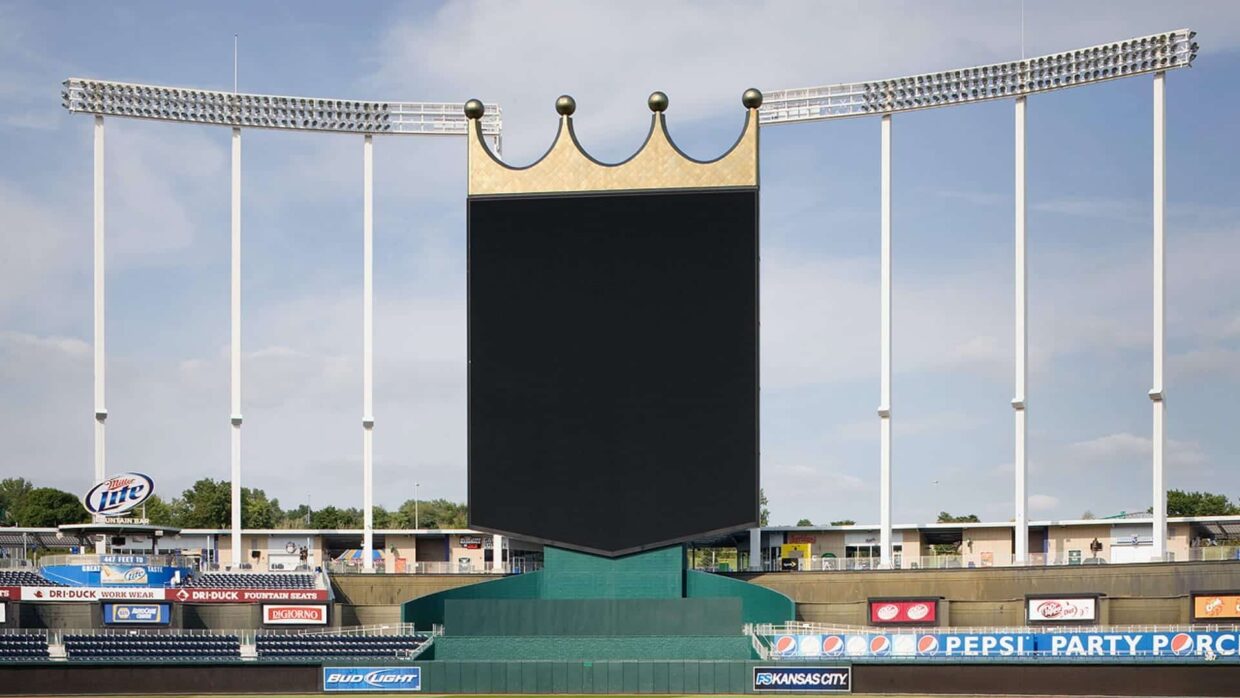

Photo © Mijie

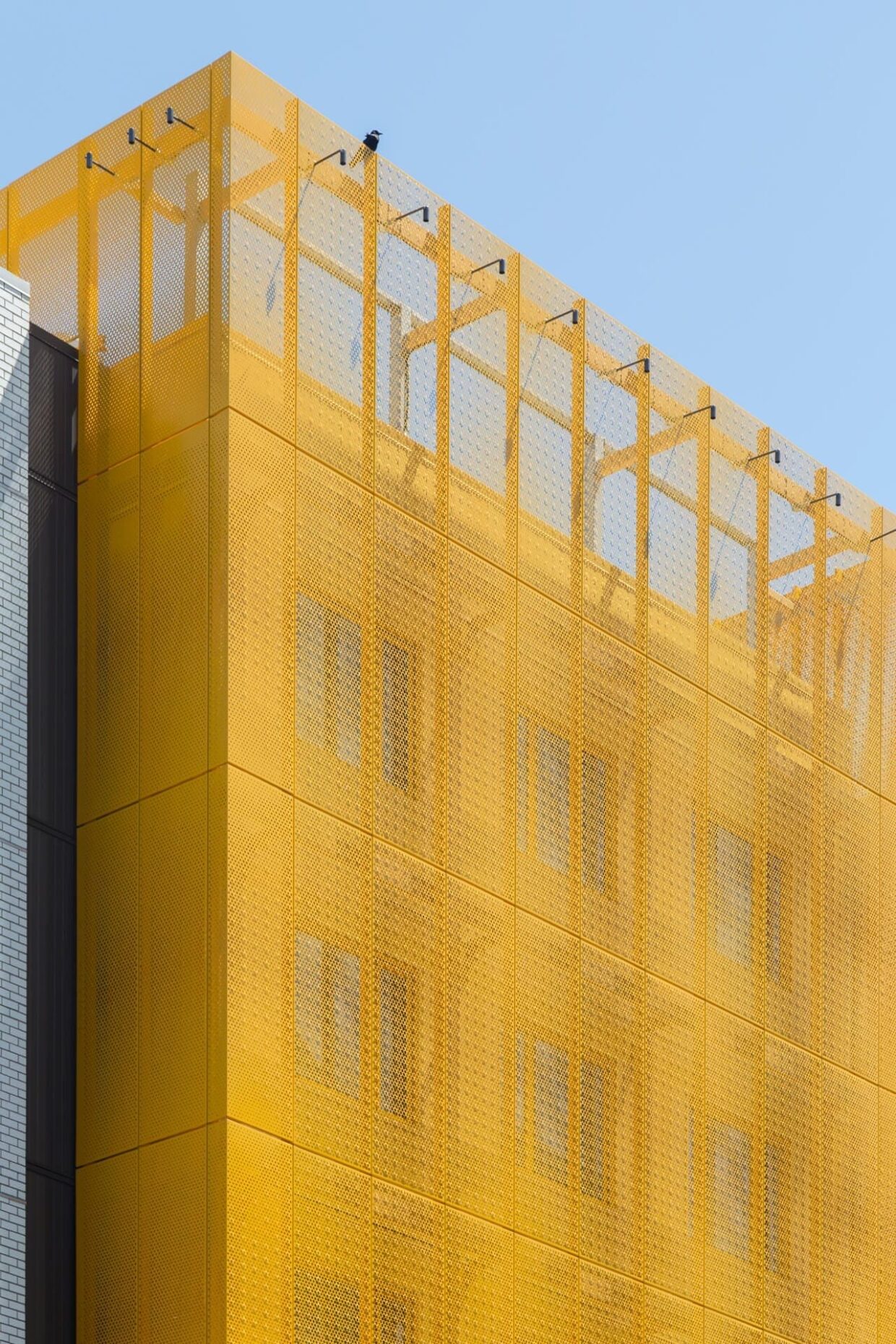

Photo © A. Zahner Company

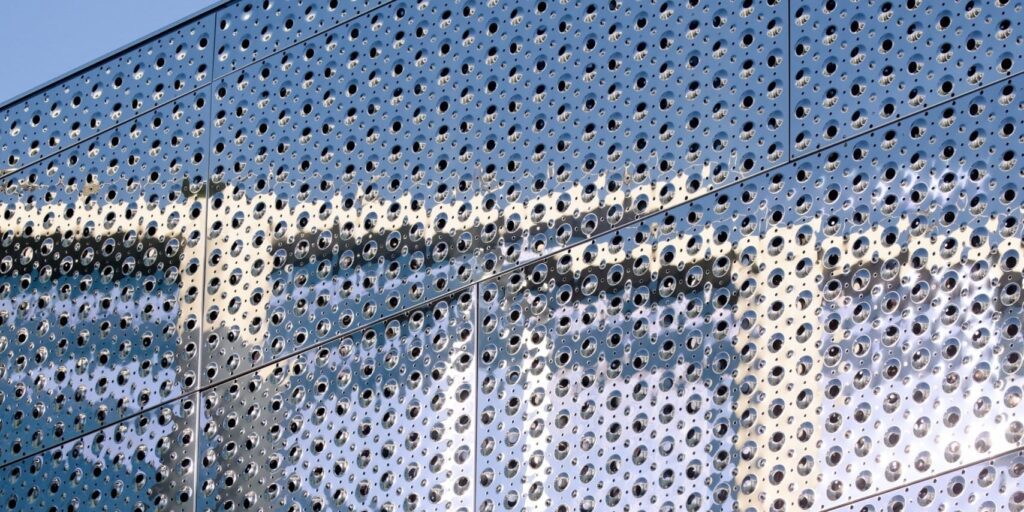

Photo © A. Zahner Company

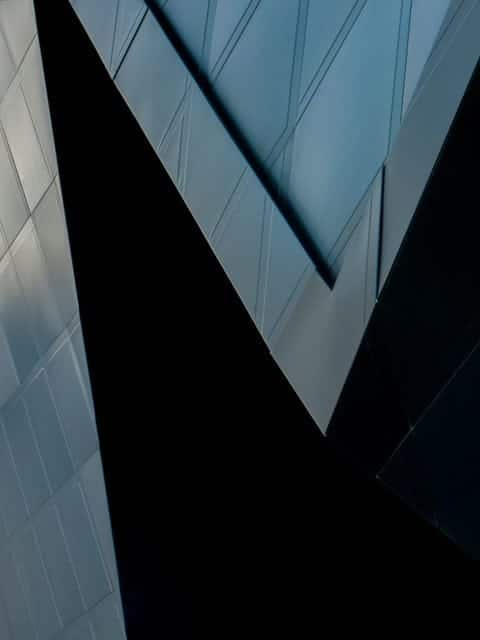

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © A. Zahner Company

There are a variety of ways to achieve bumped and indented metal surfaces. Embossing is performed while the thin metal is still in coil or sheet form. Embossing imparts a texture by passing smooth, thin-gauge metal through engraving rolls, which press a pattern into the metal surface. Embossing stiffens the metal surface, reducing the “oil canning” tendencies of the thin sheet. The embossing rolls flatten the metal for further roll forming into corrugated panel shapes or for forming flat sheets into sheet metal configurations.

Hiding Surface Imperfections with Embossed Metal

Another reason why embossed metal is selected is to hide surface imperfections. When metal comes off of a mill, it will often have surface imperfections or light scratching. A densely embossed metal surface will hide surface scratches due to its metal texture.

Metal embossing solves several problems at once: you can save money by reducing the material thickness, add rigidity to your surface, and develop a unique aesthetic, all on a metal panel which fits into standard attachment systems.

Restrictions, Panel Sizes, and More Information

Metal Embossing can be applied to a variety of metals and at nearly panel size. However, there are some caveats. When embossing is used on unfinished aluminum, the surface enhancements conceal many small imperfections and are often used in exterior applications where no other finish is provided. Embossing will not work well on anodized sheets because of the brittle nature of the anodized surface.