Copper is a malleable and ductile metal with high thermal conductivity. A freshly exposed surface of pure copper has a reddish-orange color, which will quickly patinate under normal conditions.

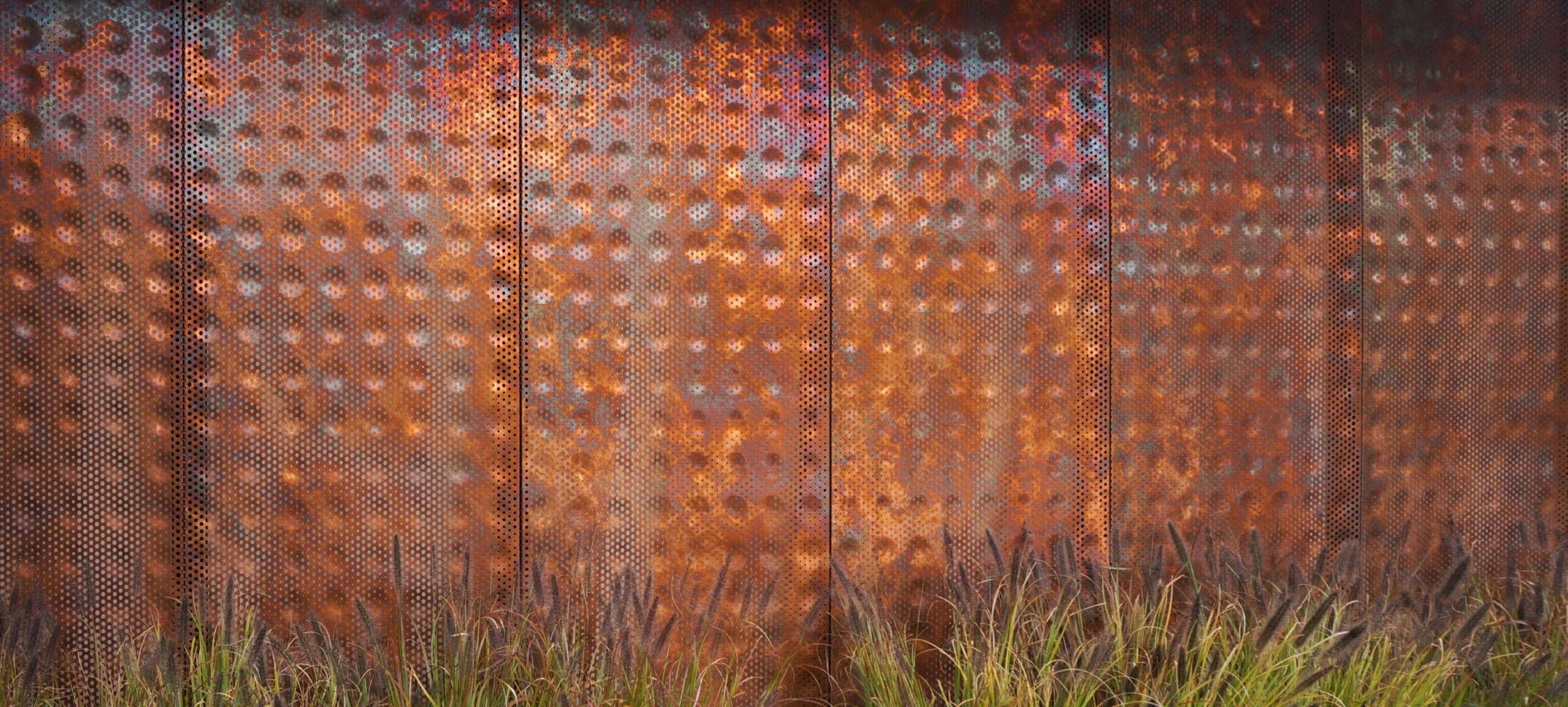

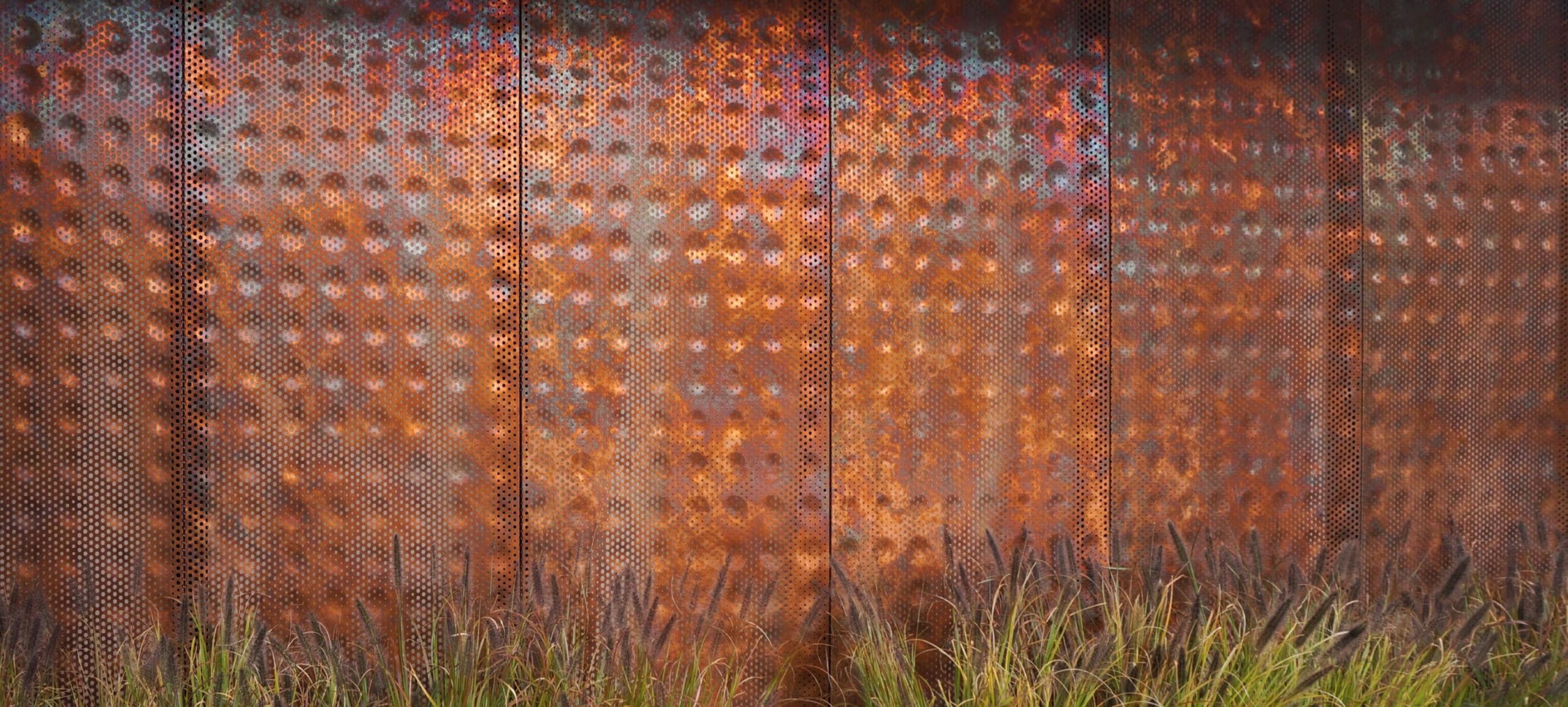

New copper can look as if it is on fire in low twilight, when the red wavelength of light is more prevalent. The surface of new copper is specular, moderately polished from the cold rolling process, imparting a burnishing effect on the copper. Like gold, copper absorbs most strongly on the red region of the light spectrum, hence reflect more intensely on the red scale. Thus, cloudy days have only a minor effect on the reflected light from gold and copper surfaces.

Eventually, the surface of copper will oxidize and decrease in reflectivity, giving way to earthy tones of a dark matte, surface. After several years, the appearance will show signs of green verdigris in its crevices, and may completely turn green over the course of decades.

Today, the development of these green copper sulfate patinas has greatly diminished. The reason is that the atmosphere is cleaner and less polluted with sulfur compounds necessary to form the green patina. Thus, it takes considerably longer today to naturally develop the green patina in many areas of the world.

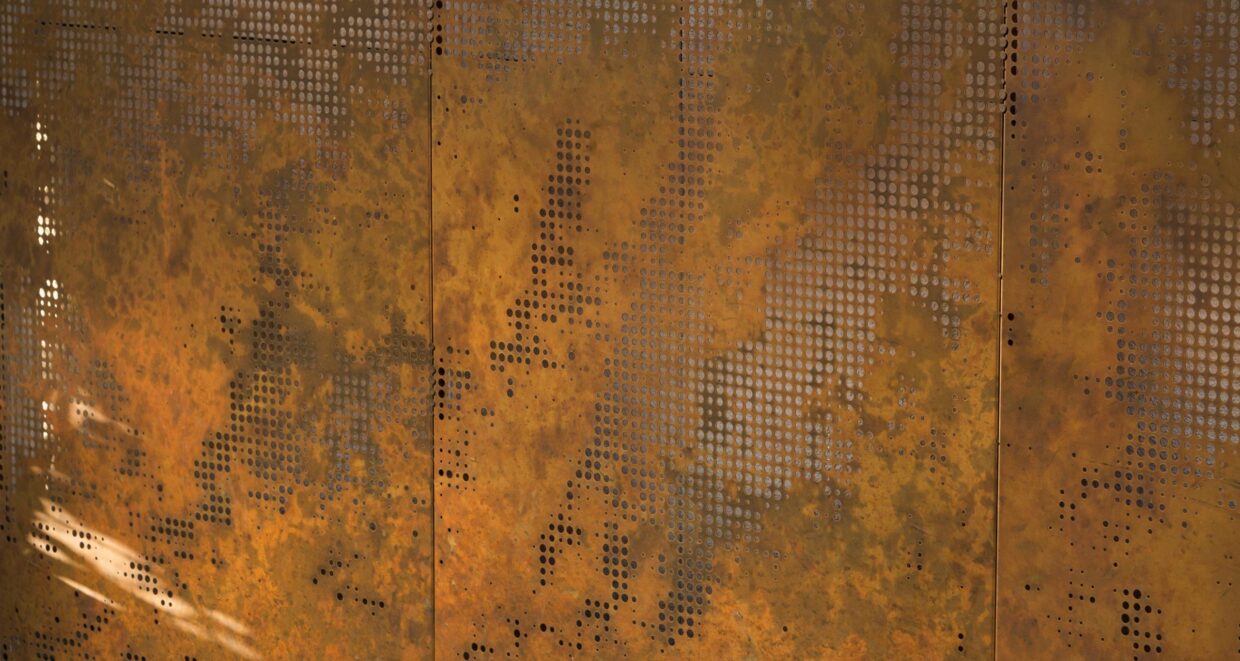

Photo courtesy of Herzog & de Meuron

Natural Weathering of Copper Alloys

Copper is a fascinating metal to use when considering color. No other metal comes close to offering the variety of color that copper can develop. Copper seeks other elements to develop compounds that possess unique color attributes. Essentially, the copper surface, like most metal surfaces, seeks components in the atmosphere and surroundings to combine with. Over long periods of time, the metal surface develops compounds that resemble closely their mineral equivalent. Once this occurs, the copper compounds are defiant and stubborn. Further change is inhibited.

For instance, copper roofing, exposed for a century or more, develops a thick, beautiful green patina. This patina is typically the result of sulfur and oxygen from the air combining with the surface copper atoms. Water intermixes the reaction, and, over time, the surface develops a hydrated copper sulfate not unlike that of the mineral bronchantite.

Today, the development of these green copper sulfate patinas has greatly diminished. The reason is that the atmosphere is cleaner and less polluted with sulfur compounds necessary to form the green patina. Thus, it takes considerably longer today to naturally develop the green patina in many areas of the world. In dry climates, the green patina may never develop; and in coastal regions, chlorine is added to the surface of copper alloys to develop a blue-green patina of copper chloride. This will appear more rapidly, first as a very pale green across a darkening surface.

Custom Prepatinated Copper

Zahner has developed proprietary techniques to prepatinate copper sheets with deep, rich patinas not unlike those that formerly took several decades to develop naturally. Some of these proprietary techniques can develop the rich brown tones of cupric oxide on the copper surface. There are also techniques that can develop browns, yellows, and oranges, in various hues, to create beautiful colors from the chemical combination with copper oxide.

The process of patination is an art as much as it is a science. The effects on color development are highly dependent on ambient conditions and surface preparation processes. The metal surface must be thoroughly cleaned. Only people experienced with working with acids and strong bases should perform these pretreatments, as extreme caution must be exercised when working with such chemical treatments. The use of proper safety equipment, eye protection, rubber gloves, and a respirator is essential. If producing these on a large scale or in a factory environment, the patina process must be performed in a well-ventilated space with EPA-regulated waste disposal.

Field-applying patina to a surface is extremely difficult. Success is fleeting and rare. There are just too many variables to control, and the necessary solutions can be quite hazardous. What looks successful one moment on a field-applied patina can deteriorate quickly as the weather conditions change or as the oxide unzips from the copper and washes off the surface.

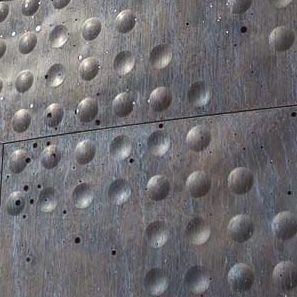

Copper alloy surfaces, whether they are prepatinated or not, continue to age. The aging occurs at a progressively slower rate as the copper surface reaches a chemical equilibrium. For example, bronze statues, exposed to the weather for centuries, often develop a darkish “bloom” in the form of a spot or streak. These localized changes are the product of natural pollutants and the further aging of the surface.

The predominant oxide to develop on the surface of copper alloys exposed to the atmosphere is cuprous oxide, Cu2O. This oxide is essentially the mineral cuprite. The color is reddish brown, but often exhibits a range of color from orange to yellow, even purples, as refined in the Dirty Penny copper developed by Zahner. These are “interference colors” created by the thin oxide layer over the reflective base material. Cuprous oxide is insoluble in water. It is a semiconductor of electricity, which is part of the reason why copper continues to oxidize further beyond the basic oxide. Cuprous oxide forms readily on copper alloy surfaces in the presence of moist air. The minerals of copper undergo a very slow aging process, though the process is somewhat faster when near the sea.

Another somewhat common mineral formation on copper alloys combines carbon dioxide and forms carbonates over the initial cuprous oxide layer. The carbonate mineral forms are malachite and azurite. These relatively uniform corrosion products are difficult to artificially create.

All copper and copper alloy surfaces exposed to the atmosphere undergo changes. On a molecular level they seek various compounds from the atmosphere and readily combine with them. They actually remove pollutants from the air, albeit very slowly, by combining with sulfur dioxide and carbon monoxide to form mineral compounds that effectively trap the pollutants.

Copper Coating on Other Metals

Occasionally, copper is used as a coating on other metals. Typically, it is plated over steel or stainless steel with a thin-plated coating of nickel sandwiched between. Copper plate is used on decorative interior and exterior fixtures. The plating will, if not coated an oxide-inhibiting lacquer, tarnish and weather similar to solid copper. Stainless-steel sheets with copper plating are available as well for use as an exterior cladding material.

*Although we do not offer supply only sheets for unpatinated copper, we are happy to custom fabricate based upon your project’s needs. We selectively partner with vendors offering the highest quality materials available in many sizes and thicknesses. Please call for details.