Radius Reduction provides designers with a range of automated panel options with crisp, miter-like edges. It provides an alternative to brake-folding metal, and gives increased accuracy and sharper edges.

Radius Reduction builds on the concept of v-grooved metal. V-grooving is a traditional machining technique which goes back to the 1930s. Also known as v-notching, or v-cutting, it is an innovation which improves accuracy and creates elegant, crisp folds in metal.

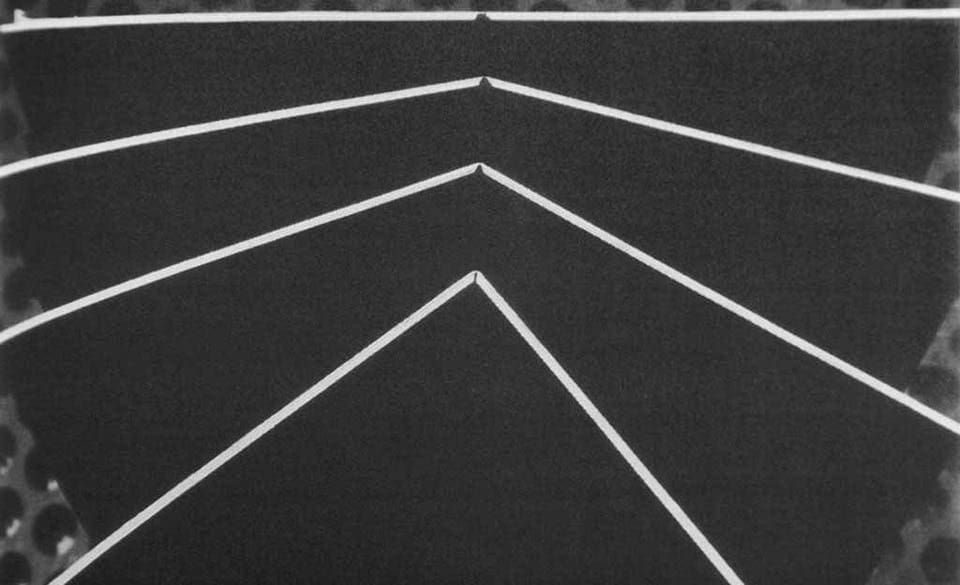

V-grooved metal enables designers to develop joints and corners with perfect dimensional accuracy. The process works by cutting a “v-shaped” section into the backside of the thick metal material. The metal is then folded or formed along this groove, allowing for precise, folded edge with minimal radius-edge.

Photos © A. Zahner Company

Radius Reduction: Automated V-Grooving

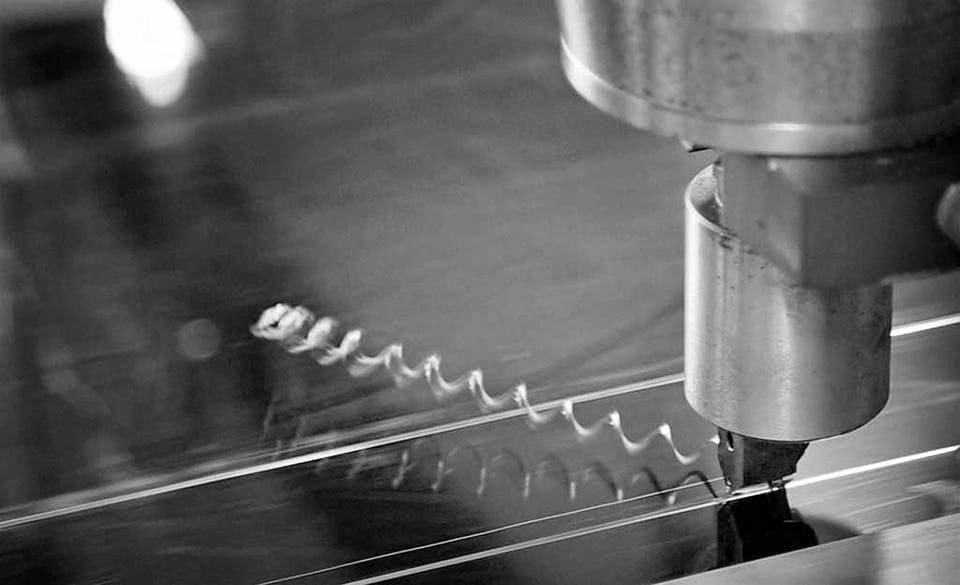

Removing a v-section from the metal is not unheard of in the fabrication of metal panels. However, the available industry machinery for producing this process is limited in size, and can only operate along perpendicular axis.This limitation created an opportunity. In the early 21st century, Zahner began developing its own technology, theRadius Reduction machinery.

While a typical sheet metal machine capable of grooving metal will work on standard widths up to 4 ft, Zahner’s Radius Reduction machinery is built from the ground up to handle widths exceeding 7 ft, and can groove a metal sheet up to 20 ft on the diagonal.

Diagonal movement is where standard machinery is truly most limited. Typical processes are limited to lateral movement. These machines work by running a sheet horizontally through a standard bit. The result is perpendicular v-grooves in a metal surface.

These older machines can be rigged with a template to produce small angled metal, but it becomes costly for attempting to rig larger sheets to run across the panel. So Zahner worked with a milling manufacturer to produce its own custom machinery for creating notched edges in any direction across massive panels and developed a precise formwork using this technology.

Photo © A. Zahner Company, Courtesy of John Wiley & Sons

Photo © A. Zahner Company

Why Radius Reduction is preferred over Brake-forming

Radius Reduction provides two primary benefits over brake-forming and other panel-folding options: dimensional accuracy, andorigami aesthetics.

When a metal edge is created by press-brake forming, the typical fold is two times the thickness of the metal. Sometimes referred to as a 2-T radius bend, this standard fold is rounded and smooth in appearance.

While skilled press-brake operators have little problem consistently repeating the bending operation, achieving consistent parts with brake-formed edges is more difficult. This problem becomes compounded with thicker sheet and plate materials. When brake-forming heavy materials, inconsistencies will develop causing edges to misalign from one part to the next. By using various methods for Radius Reduction, the panel will be clean, consistent, and precise.

Described technically, the accuracy in setting a v-cut is usually to within 0.005 inches (0.127 mm). The v-cut locates where the bend is to occur, so the folds can have enormous precision. A press-brake requires the matchup of a curving edge and is prone to slip slightly, even with an accurate back gauge. The V-cut allows for the development of miters. Once folded V-cut miter will match up to another with high accuracy.

Photo © Justin Maconochie

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © A. Zahner Company

Photo © A. Zahner Company

What can you produce with Radius Reduction?

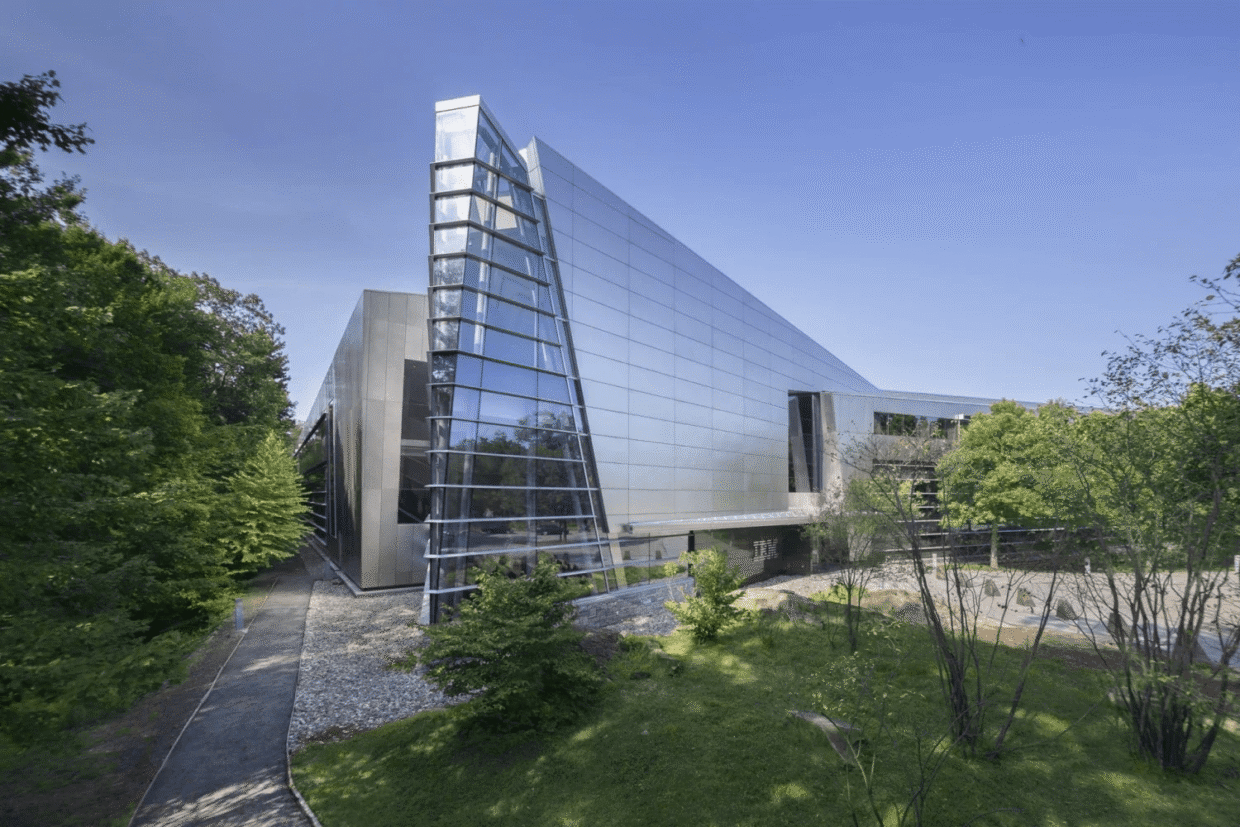

Zahner has used this technology on a number of projects. It can be used on both a large scale as well as a small scale. The first project to benefit from this technology was the Zaha Hadid-designed Broad Museum in Lansing, Michigan. This building has long, crisp edges on its many pleated stainless steel forms. It is an extraordinary example of how the technology can be used on a metal system.

The Burberry Flagship in Chicago uses Radius Reduction for its exterior black metal system. Zahner was brought onto the Burberry project to develop a black stainless steel facade and lighting system which would meet the highest standards of museum-quality metalwork desired by Burberry.

Photo © A. Zahner Company

Photo © Robert Heishman

The use of Radius Reduction enabled the Zahner team to use a heavy-gauge metal without sacrificing edge-quality. Using the heavier material reduces any oil-canning or undulations in the metal surface. The system is also deeply set, providing a strong sculptural feel to the building’s architectural accents.

Developing precision building designs with Zahner

Very few manufacturers are set up to do this process on a large scale. Those that can are typically limited to small rectangular panel shapes due to standard machinery limitations. To learn more about how to integrate Zahner and these advanced production techniques into your design, contact the Zahner sales team and get started.