Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

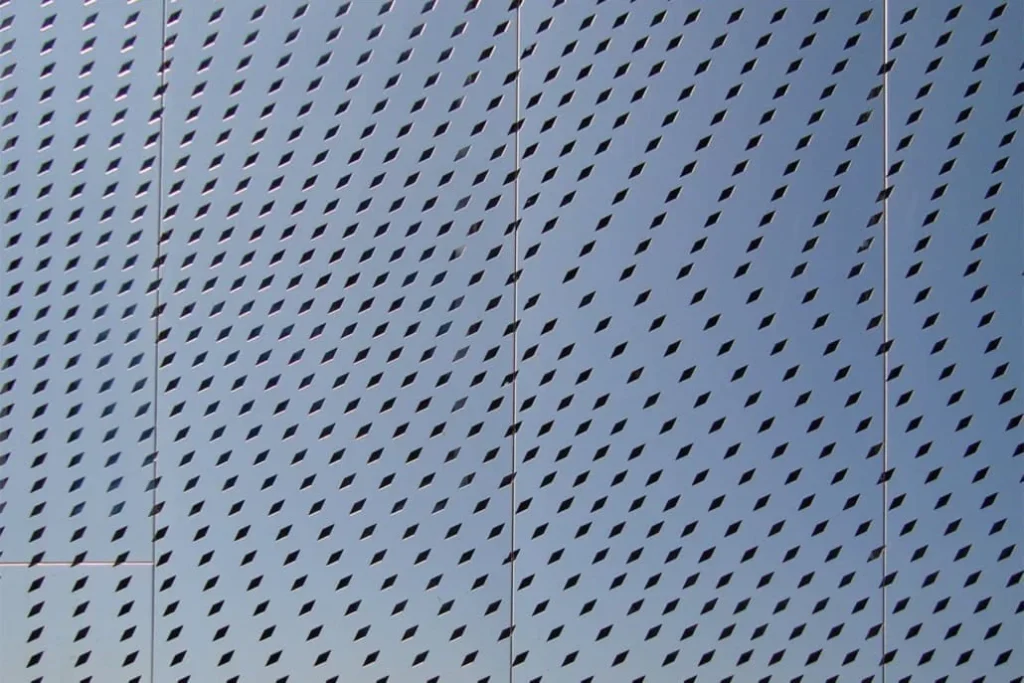

Perforated metal panels provide numerous design and construction advantages. From beauty and durability, to energy efficiency and sustainability, perforated metal adds style to any environment.

Another key benefit perforated panels offer is that they can be designed to meet a variety of open area surfacing requirements.

Why the Open Area of Perforated Metal Matters

Here are the key factors in perforated metal panel open area calculations, and what architects, designers, and specifiers need to know when considering the right open area for their perforated metal projects.

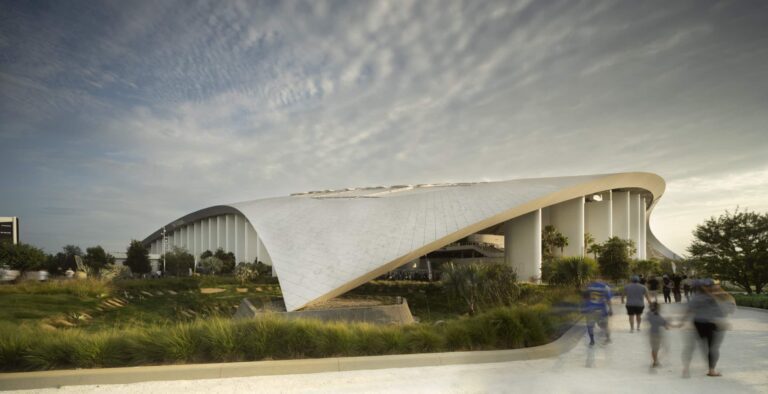

Photo by Bernard Andre.

Ventilation and Airflow.

The open area determines the extent to which the panel allows air and light to pass through. In applications such as parking garages and building facades the open area directly affects the efficiency of airflow and ventilation, to better handle exhaust emissions, heating and cooling.

Sound Absorption & Acoustic Performance.

Perforated metal panels are effective at diffusing sound and reducing acoustic emissions. The open area in the panels allows sound waves to pass through the perforations, leading to better acoustic performance. Perforated metal can even be used as a selective sound absorber, tuning out a certain band of frequencies if necessary. (Note: Some metals are better than others when it comes to sound absorption.) Acoustic panels with carefully calculated open areas can effectively attenuate noise, creating more comfortable and peaceful environments.

Photography by Alexander Miller

Light Transmission.

When used for facades and sunscreens, where the interplay of light and shadow enhances architectural aesthetics, the open area affects the amount of light that passes through the perforations, shaping the visual effect. Designers can manipulate the open area to achieve specific lighting effects and control the intensity of daylight as it moves throughout the day. If you want both privacy and natural sunlight, perforated metal panels also provide the perfect solution.

Lighting Effects.

Perforated metal not only lets light enter a building, it can also be backlit to project light outwards. This creates the opportunity to design glowing facades that are eye-catching, provide useful privacy benefits, and meet open area requirements.

Photo by Cornelius Hayes, ARKO | © A. Zahner Company

Design Originality.

The pattern of perforations, combined with the open area, influences the overall visual appearance of perforated metal panels. Different open areas can yield varying levels of transparency and opacity, allowing architects to use drawings, photos, patterns, or other unique designs.

Energy efficiency and improved building performance.

Perforated metal panels provide light and ventilation modulation, thereby improving HVAC load and usage. And since perforated material allows natural light to enter the building, less artificial indoor lighting is needed, further reducing the building’s energy usage.

Photos © Ben Coffman.

Structural Integrity and Weight.

Open areas reduce the overall weight of the panel, as well as the structural integrity. This can be advantageous in applications where weight is a concern for installation, weather resistance, and durability. Perforated panels are easier to handle and work with, and also reduce the load on a building’s framework. Transportation costs (and carbon footprint, more on that later) can also be less compared to a similar load of non-perforated sheet metal.

Manufacturability.

The percentage of open area in perforated panels can cause issues during manufacturing and fabrication, as the amount of material being removed can cause warpage. In some cases, the warpage can be removed in a post-punch flattening process. Material type and thickness also come into play, which is why mockups are recommended best practices for custom perforations and high-design materials.

IMAGE © MIKE SINCLAIR

Material and Cost Efficiency.

Optimizing the open area ensures efficient use of materials, which can have cost implications in large-scale projects. By carefully considering the open area, architects can strike a balance between functionality, aesthetics, and cost-effectiveness.

Aesthetic appeal.

Architects love working with perforated metals of all types — stainless steel, weathering steel, copper, zinc, and aluminum — for the style and flair they give to buildings, courtyards, lobbies, arenas, stadiums, and other structures. With perforated metals, architects can select from a wide variety of finishes and hole shapes that can be arranged to create patterns, images, logos, scenes, and signage.

Sustainability.

Buildings constructed with sustainable and environmentally friendly materials are in high demand by building owners. Perforated metal is infinitely recyclable, reducing the depletion of our natural resources. Furthermore, recycled metal is often used in the manufacturing process for perforated metal panels, and the waste created during the manufacturing process is also recyclable. And the reduced weight of perforated metal means less fuel is required to transport it to a jobsite.

PHOTO © THAI & LU.

PHOTO © THAI & LU.

Decoding the Open Area of Perforated Metal Panels

The open area of a perforated metal surface or panel is a critical factor that significantly impacts performance and suitability for specific applications– a crucial aspect to consider when specifying open area percentages.

The open area refers to the proportion of perforations to the solid metal sheet. For instance, a profile with a 30% open area signifies that 30% of the sheet consists of punched holes, while the remaining 70% constitutes the unperforated portion of the metal surface.

This ratio has a direct influence on various aspects of the perforated metal panel’s functionality and aesthetic appeal. For example, 50% open area is often a default request. However, that can cause problems with extreme transparency, image quality, durability, and manufacturability.

PHOTO © A. ZAHNER COMPANY.

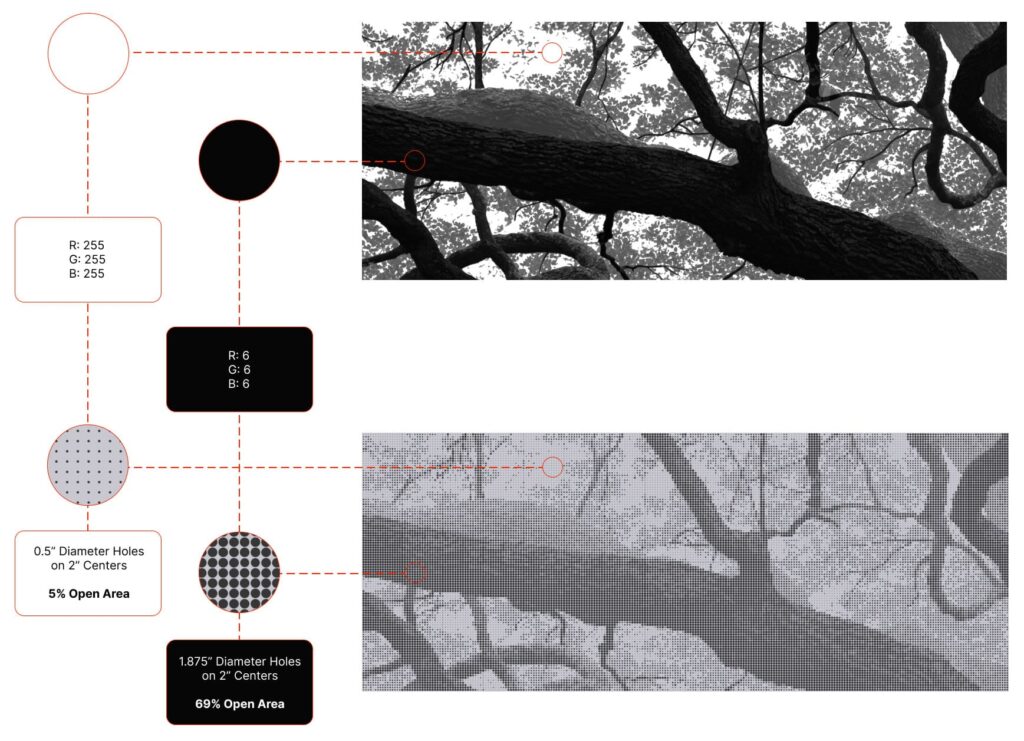

The average open area percentage for a custom perforation pattern derived from imagery can be calculated by summing the areas of all the perforation holes and then dividing that sum by the visible surface area of the entire scope.

PHOTO BY TEJAS DOSHI | ARKO

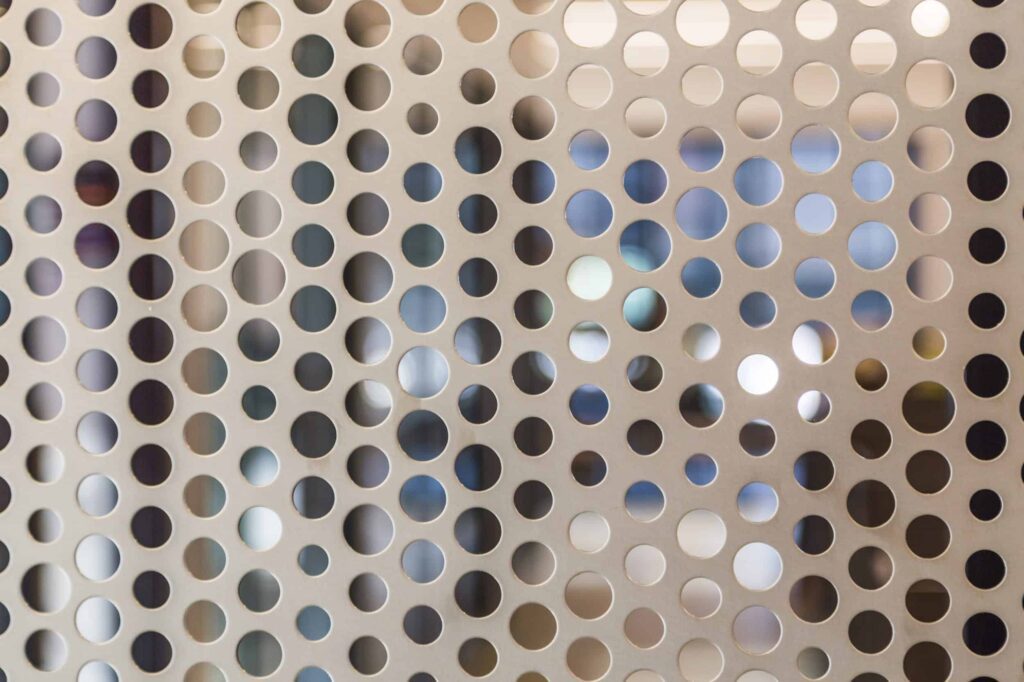

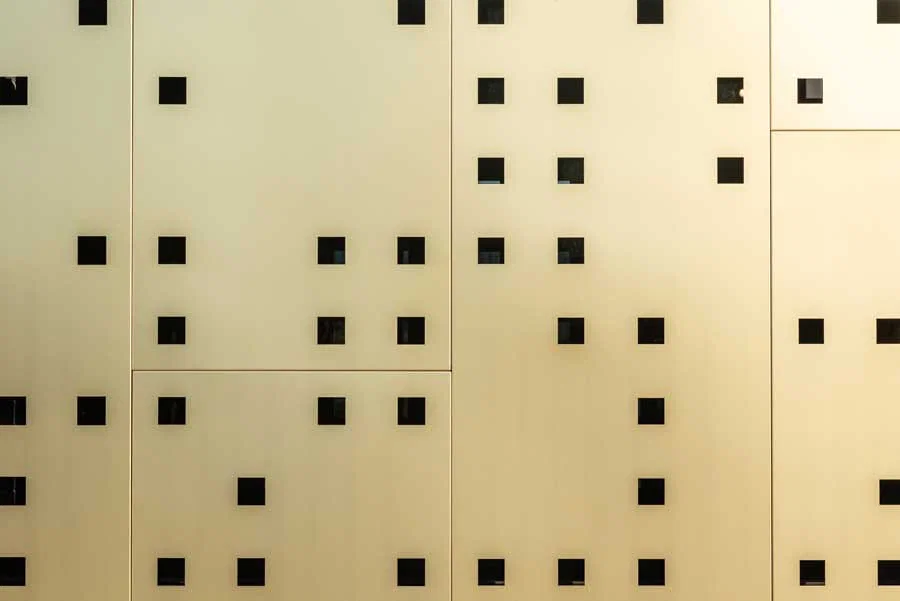

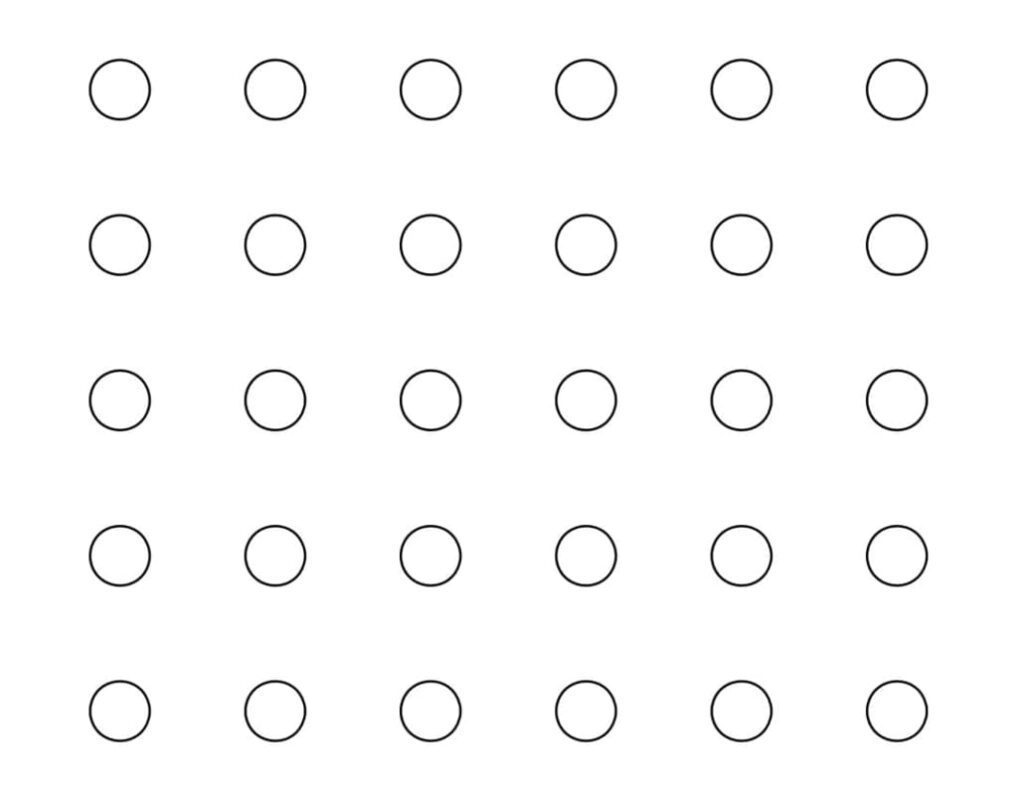

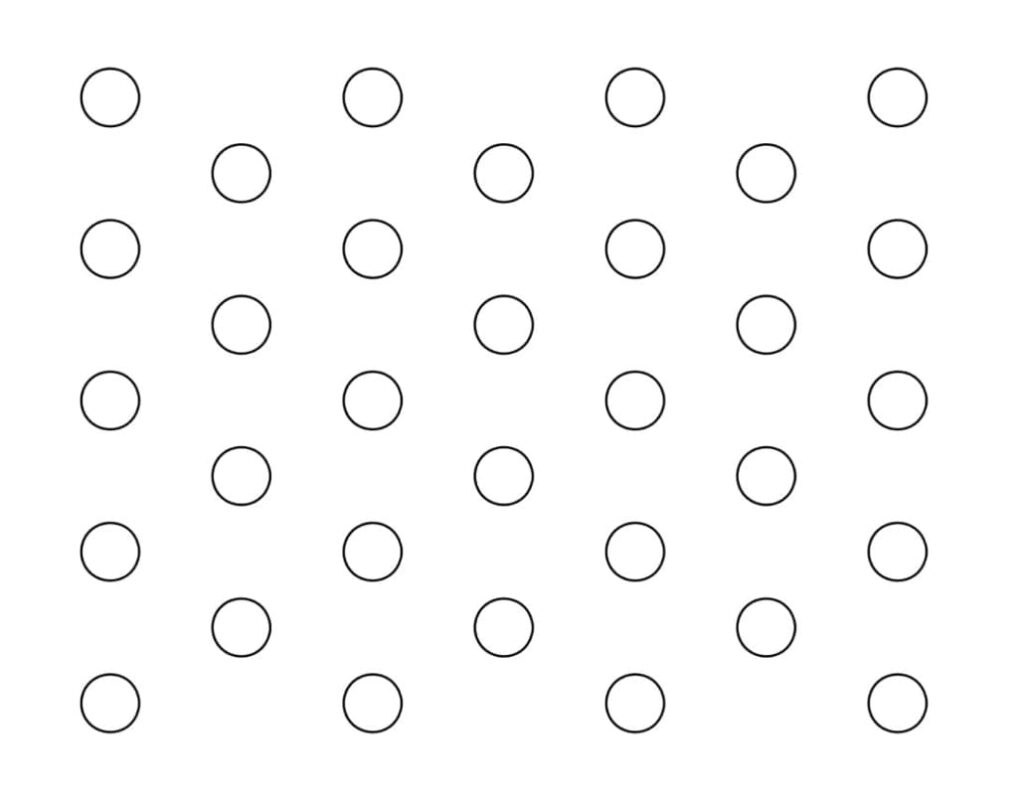

Each distinctive perforation profile, from classic round holes to hexagons, slots, and squares, requires specific calculations. The open area percentage of round holes with a straight arrangement varies from that of round holes in a diagonal orientation.

Your design, fabrication, and manufacturing partner should assist with all the essential formulas, calculations, and other considerations to determine the correct percentage of open area for your project.

PHOTO © JAIME NAVARRO.

PHOTO © WADE GRIFFITH.

PHOTO © JAIME NAVARRO.

PHOTO © A. ZAHNER COMPANY.

Perforation Orientation and Size: How They Impact Open Area & Aesthetics

Perforations can be square, rectangular, hexagonal, and oval — but by far the most common perforation is a circular, or round, perforation.

Here are the most common round perforation patterns:

The interplay of hole size and orientation – the distance and angle relationship between hole centers in adjacent rows – plays a pivotal role in achieving the desired open area percentage. For example, staggered perforations allow the holes to be more closely grouped, allowing for more open area percentage.

The intended function of the perforated metal sheet guides your choice of open area percentage, hole size, shape, and orientation.

It’s important to also understand the implications of open area percentage and hole sizes and patterns during the fabrication and manufacturing process. Standard (single-size) perforations are applied using machinery that generally does not allow for custom sizes for field-dimensioned panels. This is where a custom perforation pattern with multiple hole sizes can facilitate more advanced design solutions.

PHOTO © CHRISTIE RACHELLE.

For example, Zahner ImageWall® is standardized around a maximum perforation size of ⅞” and minimum perforation size of ¼”, spaced on a square 1” grid. This provides a wide range of possible open area percentage values – from a minimum of ~5% (all ¼” holes) to a maximum of ~60% (all ⅞” holes.). The values established between these two endpoints are a function of the image itself and the relative proportion of black-to-white values required to create an attractive image that also meets the specified open area percentage requirements.

In some cases, advanced design concepts are removed from consideration when open area percentage requirements are necessary, but custom perforations can still be used to meet both the design goals as well as the open area percentage requirements.

It’s also important when considering open area percentages to take into account how open areas can be concentrated to meet a specification. At Zahner, we’ve created a number of techniques to adjust the lightness and darkness of an image to selectively add black or white (more holes or fewer holes) within a specific region of an image to achieve the target open area percentage.

PHOTOGRAPH BY MATT BRODEUR

Elevating Design and Functionality With Perforated Metal Panels

Perforated metals panels are some of the most flexible and affordable in terms of design possibilities and budget. Here are the most popular applications:

- Words, illustrations, or images

- Classic round, rectangle, or square patterns

- Modern geometries and futuristic shapes

- Combinations of two or more of the above

Perforated metal panels blend form and function in balanced, yet dramatic ways. From sleek facades to decorative interior features, these panels create an interplay of light and shadow, infusing spaces with character and charm.

With their wide range of utility in decorative screens, sunshades, privacy panels, and artistic installations, they add visual interest in any setting including commercial, residential, institutional, and even urban landscapes.

PHOTO BY PIERRE GIRAD | ARKO

The open area percentage of perforated metal panels is a crucial factor to consider when specifying these design elements. Not only does it determine the amount of light, air, and sound that can pass through a panel, but it can also have a significant impact on the panel system’s perceived image or pattern resolution, durability, and material strength. Careful consideration of the open area ensures a perforated panel system will align perfectly with a project’s specific requirements.

And the sustainability benefits of perforated metal panels should not be overlooked. The infinitely recyclable quality of metal makes them a preferred choice for eco-conscious designs, contributing to lower carbon footprints and greener architectural practices.

Perforated metal panels, with their diverse uses, adaptability to various settings, and customizable attributes, have become indispensable design elements for designers and architects worldwide. The ultimate combination of sophistication and style, they are sure to leave an enduring mark on contemporary architecture for many years to come.

White Paper

Download the Open Area Calculations White Paper

For more information about Zahner’s perforated metal panel design and installation support, design advisory services, or to learn more about Zahner ImageWall or ImageLines® custom perforated metal panels, call +1 (816) 423-8354 or contact us here.