Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

As the number of cars increases exponentially around the world, parking has become one of the critical issues of modern architecture, engineering, and design. Yet parking has often been reduced to the most basic design standards, leading to poor public perceptions, and increased community oversight and design guidelines that must be closely followed.

Functional, well-designed, and patron-friendly parking garages are valuable infrastructure assets for any community when they are produced thoughtfully with the latest parking design practices and principles. Most architects, engineers, and planners are embracing these principles of good parking design and building far more aesthetic and integrative structures.

To meet the aesthetic goals of a parking structure project, metal facades and screens are often considered for their durability, functionality, and beauty. They can be attractive and engaging design element additions for any parking garage, however, they do require forethought and planning to reduce risks and win the support of all stakeholders including architects, owners, contractors—and the community.

Here are three crucial facade factors to consider when planning, designing and building your next parking structure project.

The Wynwood Garage features a painted aluminum facade with perforated planes that create multiple sight-lines. The wall is also designed to allow for additional artwork to be hung on the facade.

PHOTO BY TEX JERNIGAN, ARKO | © A ZAHNER COMPANY

Parking Garage Facade Designs That Make a Statement

The aesthetics of facility design and related facades have become extremely important to communities across the country. Simple screens or masonry veneers often don’t do enough to shield or enhance parking garage designs.

And designers today are increasingly seeing parking garages as an opportunity to create public art, revitalize overlooked urban settings, and create a more pleasant street-side view and walking experience.

The infinite design possibilities and sustainability qualities of metal facades make them a good option. Custom architectural metal facades are aesthetically striking and more affordable and accessible than ever thanks to new technologies and innovative fabrication techniques. Custom metal facade options are numerous, including:

- a variety of metals, colors and finishes;

- perforated imaging with unlimited choices of hole patterns, sizes and shapes; and

- custom painting, punch pressing, engraving and water jetting for unique designs.

Perforated metal panel facades—because of their recyclable metal construction—may also earn sustainability credits for certifications and other community requirements. And they do more than add aesthetic value. Perforated or louvered metal facades help meet open-air garage requirements with their uniformly-distributed openings. They also control air, and block car headlights, sunlight, noise and wind, in addition to creating a beautiful and interesting design.

Closeup of the custom metal facade for the Brickell Flatiron Parking Garage, produced by Zahner.

Photo by Curtis Smith | ARKO © A. Zahner Company

Facade Engineering: Embeds That Increase Acceptable Tolerances and Reduce Risk

Facade engineering is crucial for resolving aesthetic and structural issues to achieve the effective installation and long-term durability of your metal parking garage facade.

One of the most important engineering considerations is connecting facades to concrete structures.

Concrete embed anchors and embed anchor channel systems are commonly used to connect concrete floors, walls, and piers to facade components. These anchors must be carefully cast in place during onsite construction pours, or precast manufacturing.

Error rates can be high in these situations and the cost of embed misplacement can be expensive. Embeds tend to move during placement and pouring, and fractions of an inch can trigger revisions to attachment points that can create a domino effect of change orders.

Embed plates can also be retrofitted to concrete structures, however, the risk of drilling and damaging rebar or Pretension cables goes up, and the cost of installation can set budgets and calendars back significantly.

For our metal parking garage facade projects, we recommend removing the variation and risk of embed placements by using weldable embed plates designed by our own engineers. Oversized weldable plates are easier to cast in place or spec during pre-casting, they leave more margin for error, and they expand the acceptable range of tolerances.

Our onsite welding methods and results are easier, safer, and higher quality, requiring minimal labor and inspection.

Easier embeds translate into better performance, improved cost control, and happier contractors.

Detail of the Drop & Lock attachment system on Wynwood Garage.

© A. Zahner Company

Facade Installation: Combining Talent and Technology to Deliver Superior Performance

With engineering loads calculated, and weldable embed plates in place, metal facades are ready to be field welded at the proper attachment points.

While field welding of this kind may be cause for concern with some contractors, we’ve developed a trusted network of skilled installers who can work safely and quickly with the necessary aerial equipment and automated drawn arc welding guns that take out variation and create a perfect weld every time.

We’ve also developed our own field survey technology—SurveyLink—a real-time data link between as-designed 3D models and as-built data collected in the field. SurveyLink eliminates fragmented communications, and improves productivity by reducing field crew time and lengthy review periods typically associated with construction administration.

When facade design, engineering and installation come together in a more coordinated and comprehensive way, the benefits are significant:

- improved performance and quality;

- fewer change orders;

- faster variation resolution; and

- expedited lean construction.

Attitudes towards parking garages and their facades are evolving. And unconventional features and designs are changing the way we plan, engineer and build these critical utilitarian structures.

Collaboration and innovation are key: when the right people, process and products are combined, they can minimize the risk and increase the reward of any parking garage facade project and deliver on the needs of function, aesthetics, and durability.

Interior detail view of the Facade for the Froedert Garage.

© A. Zahner Company

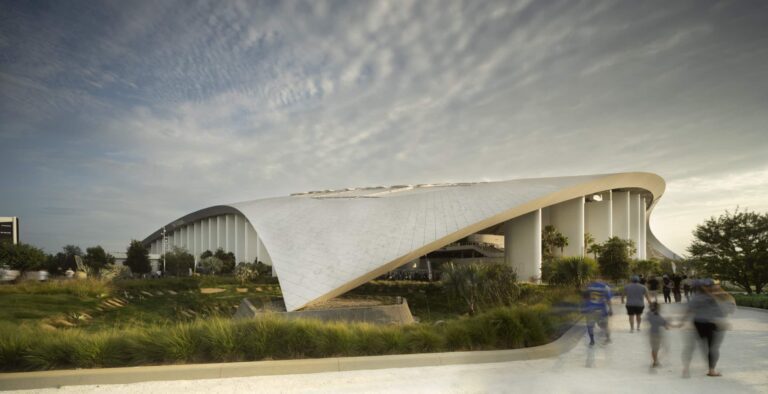

Leong Leong facade for the Miami City View Garage.

© A. Zahner Company

Zahner helps architects, owners, and contractors make any parking garage facade project more feasible, achievable and affordable. Zahner brings a blend of architecture, engineering, technology and materials expertise—all under one roof—to every parking garage project. To find out more about Zahner parking garage facade solutions, contact us or call +1 (816) 474-8882 to speak with one of our Project Specialists.

White Paper

Download this article as a white paper