Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

There is a growing acknowledgement that the need for environmental stewardship is the responsibility of everyone on this planet today. This has put greater emphasis on understanding and designing with materials with sustainable and ecological characteristics. And it has driven the need to take into account everything involved—the impact on the environment, the people working with the material, and the future generations.

The sustainability advantage of architectural metals

A robust scrapping and recycling industry distinguishes metals from other building materials.

Metals are different from nearly all other materials used in our built environment. Once the useful life has ended, the metal is collected and recycled. During the recycling, the metal is remelted and reshaped, gaining back all of its original mechanical properties. Essentially, the metal is reborn to take on a new form and purpose.

Metals are the only material used in constructing our world that can be used over and over again—forever.

| Material | Sustainability Characteristics |

| Metals | You can recycle metals indefinitely. They retain their physical and mechanical properties. Scrap has value and a robust market exists for recycling. |

| Glass | Bottle glass can be recycled and repurposed, but not plate glass. There is no scrap value and no market for scrap glass. |

| Concrete | Concrete can be crushed and repurposed, but it is expensive and requires a high level of energy. There is no scrap value. |

| Stone | Stone can be repurposed if salvaged or crushed. No scrap market exists and, as a result, there is little scrap value. |

| Asphalt | Asphalt can be repurposed, but it is expensive to do so. There is no scrap value. |

| Paper | There is a limit on how many times paper can be recycled. There is no scrap value. |

| Plastic | There is a limit on how many times plastic can be recycled. It loses mechanical properties as it is remelted. There is no scrap value. |

| Fiberglass | Fiberglass cannot be recycled and it has no scrap value. |

| Gypsum board | Gypsum board can be recycled, but most of it ends up in the landfill. It has no scrap value. |

| Composite panels | There is no market or process in place to recycle composite panels, so they end up in landfills. This includes metal-faced panels. There is no scrap value. |

| Carpet | Carpet has no scrap value and ends up in landfills. |

| Wood | A small portion of the market is repurposed, most of the materials end up in landfills. It is biodegradable and a renewable resource. |

Sustainability Characteristics

- Metals: You can recycle metals indefinitely. They retain their physical and mechanical properties. Scrap has value and a robust market exists for recycling.

- Glass: Bottle glass can be recycled and repurposed, but not plate glass. There is no scrap value and no market for scrap glass.

- Concrete: Concrete can be crushed and repurposed, but it is expensive and requires a high level of energy. There is no scrap value.

- Stone: Stone can be repurposed if salvaged or crushed. No scrap market exists and, as a result, there is little scrap value.

- Asphalt: Asphalt can be repurposed, but it is expensive to do so. There is no scrap value.

- Paper: There is a limit on how many times paper can be recycled. There is no scrap value.

- Plastic: There is a limit on how many times plastic can be recycled. It loses mechanical properties as it is remelted. There is no scrap value.

- Fiberglass: Fiberglass cannot be recycled and it has no scrap value.

- Gypsum board: Gypsum board can be recycled, but most of it ends up in the landfill. It has no scrap value.

- Composite panels: There is no market or process in place to recycle composite panels, so they end up in landfills. This includes metal-faced panels. There is no scrap value.

- Carpet: Carpet has no scrap value and ends up in landfills.

- Wood: A small portion of the market is repurposed, most of the materials end up in landfills. It is biodegradable and a renewable resource.

As noted in the chart, there is an established and robust scrap metal recycling industry. With the production of every major metal, scrap is widely used to offset the ore needed. Furthermore, it helps save energy and production time.

Let’s look at the 5 most common metals used in architecture today and their sustainability advantages.

Aluminum

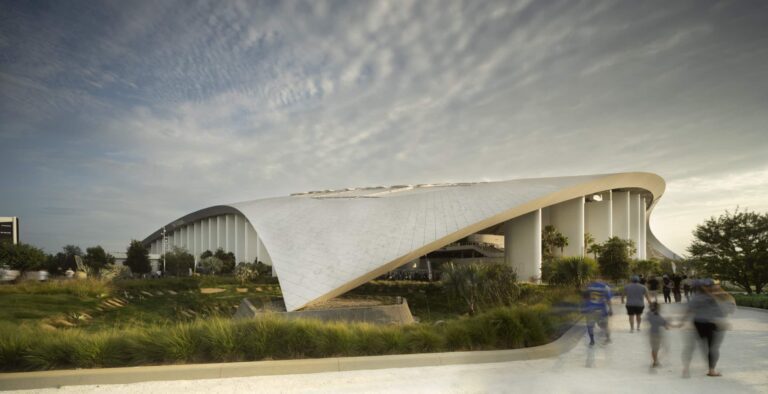

The Chrysalis Ampitheatre features an aluminum skin over a steel structure.

PHOTO © A. ZAHNER COMPANY.

In 2013, approximately 50 million tons of aluminum were produced from ore while 20 million tons of aluminum were recycled from scrap material.

Recycling aluminum has developed into an industry of its own. The collection, shredding, and melting of the metal returns more than 65% of aluminum back into the marketplace each year.

Aluminum recycling is an extremely important aspect of metal production as well. It effectively keeps costs down and reduces harm to the environment.

To illustrate, consider the past of aluminum refinement facilities. Refining aluminum from bauxite required massive amounts of energy. So much so that these operations located near hydroelectric dams in order to take advantage of the availability and economy of the electricity.

Anodized aluminum panels were used for an ImageWall installation designed by BH Architects in collaboration with Zahner.

PHOTO BY PIERRE GIRAD | ARKO

A painted aluminum soffit system at Paradise Plaza in Miami, designed by FreelandBuck architects.

PHOTO BY CHRIS WELLS, ARKO | © A. ZAHNER COMPANY

By comparison, recycling uses only 5% of the energy needed to return the metal back into raw stock to be manufactured into other forms. It has a lower melting point than most other metals making it easy to recycle and reduces energy usage tied to casting.

It is estimated that recycling reduces the need for primary production of aluminum that would have released over 100 million tons of carbon into the atmosphere.1 Additionally, it reduces dependence on the destructive bauxite strip-mining operations that scar the earth.

In the United States, 80% of the aluminum produced is from recycling. The United States has become a leading secondary producer of aluminum due to the emphasis on recycling and the high cost of energy.

Hayward Field at the University of Oregon features an aluminum Zahner ImageWall.

PHOTO BY JOEL CONRAD BECHTOLT | ARKO © A ZAHNER COMPANY

The lobby of the 6060 NCX building in Dallas features an anodized aluminum ImageWall ceiling.

PHOTOGRAPHY BY ANNIE DEVINE

Painted aluminum offers bright, bold colors to make spaces feel fun and alive.

PHOTO BY CURTIS SMITH | ARKO

The argument can be made that aluminum has a secondary effect on the reduction of energy usage. The material’s lower density allows for the creation of lightweight transportation vehicles, reducing transportation costs. The strength and lightweight nature allow for larger airplanes to move more people per unit of energy consumption. The corrosion resistance of the metal benefits the lifetime utility of aluminum, saving energy by requiring less maintenance and fewer replacements.

The oxide of aluminum is not harmful to plant or animal life. Free aluminum rapidly combines with other substances and does not dissolve in water. Human’s come in contact with aluminum every day, mostly through drinking water and cooking as well as certain cosmetics and some pharmaceuticals.

You can find more data on the environmental impact of aluminum from the aluminum industry at international-aluminium.org.

Copper

More than ever, copper is in high demand. The metal is corrosion resistant and conducts heat and electricity efficiently, making it highly desirable for the explosion of technological applications in today’s world.

Copper has demonstrated health-related benefits as well. In the last several decades, there has been substantial testing on the efficacy of various surfaces and wipes to eliminate harmful bacteria. Copper and copper alloys have performed extremely well. A study in 1983 on microbial grown on doorknobs2 found that hospital door handles made of copper alloys had no growth in microbes on the surface. This compared to other door handles made of stainless steel showing significant microbial growth.

The new Margaret M. Walter Wing of the Columbus Museum of Art features Zahner’s preweathered Star Blue™ copper.

PHOTO BY JEREMY PURSER, © A. ZAHNER CO.

A close-up of Star Blue™ copper cladding on the Kansas City Star production facility.

PHOTO © A. ZAHNER COMPANY.

Since then, there have been multiple studies on the efficacy of copper and copper alloys when it comes to combating microbial growth. The University of Southampton, in the United Kingdom performed studies where they measured the growth of microbes on various surfaces. They found that copper surfaces killed staphylococcus and enterococci bacteria in 2 hours or less. In fact, they found a significant drop in cultures within the first 45 minutes.3 The tests were performed at ambient temperatures. The US Environmental Protection Agency reviewed the study and concluded that copper is a material that can benefit public health by killing harmful bacteria. Further tests have been performed on E.coli and Legionella bacteria and returned similar results.

Coating the copper in any way can damage the antimicrobial benefit. Copper alloys will tarnish from humidity and moisture on the surface and from fingerprints. The polished surfaces seem to perform the best in this regard because they offer little foothold for the bacteria and are easier to clean. The satin finishes hold oils and moisture and will spot from tarnishing.

An ImageWall feature wall, built with Zahner’s Dirty Penny™ copper, makes a bold statement in the lobby of AECOM’s Cleveland office.

PHOTO COURTESY OF AECOM BUILDINGS AND PLACES

Dirty Penny pre-patinated copper panels clad the 15 Renwick building, designed by ODA-Architecture.

There have been concerns in the past regarding the runoff from copper surfaces entering streams and human water supply. Studies have addressed these concerns. For example, an extensive study of the San Francisco Bay area from 1993 to 1999 was performed to determine site specific water quality criteria for copper and the ability to predict the levels of copper toxicity using the Biotic Ligand Model (BLM) in estuary waters.4 The tests analyzed the estuary’s common blue mussel, Mytilus edulis. This species of mussel is considered by the US Environmental Protection Agency as the aquatic animal most sensitive to copper exposure in salt water. Data was collected three times a year from 16 to 26 sites throughout the bay area from 1993 to 1999. The results of the findings from 487 site and data specific observations concluded there was little risk in the estuaries tested.

As for potable water, consider that for decades water has been delivered to modern homes by means of copper tubing and brass fittings and forgings. There have been no known effects from copper tubing used to deliver water to homes. Copper piping continues to be the method of choice for many homes.

Copper production does have a checkered past. Mining practices in the last century have negatively impacted the environment. One of the biggest environmental impacts has been the trailing pond that contains the waste material used to extract the ore.

Also, copper production has required a lot of energy both in extraction and in refinement. For every 100 kilograms of rock removed in the mining pit, about 1 kilogram of copper is obtained.5

Today, mitigation programs and new processes are successfully being used around the world to help address the trailing pond issues. And advancements in copper production have reduced energy consumption by over 50% compared to just a few decades ago.

Stainless Steel

Stainless steel finished with selective polishing creates a unique effect for signage at CVS’s Las Vegas flagship store.

PHOTO © A. ZAHNER COMPANY.

The forms of stainless steel alloys used in art and architecture have no toxicity. The chromium and nickel as well as other substances are tightly bonded in the metal matrix that forms the alloy. Under normal and expected exposures and use of stainless steel, no release of chromium or other elements will occur.

Stainless steel alloys are considered hygienic and are acceptable for drinking water, food preparation, dairy operations, and medical devices including implants. It is used in hospitals, clean rooms, restaurants, bathrooms, and more.

The Fisher Center for the Performing Arts at Bard College, designed by Frank Gehry architects, features Zahner’s Angel Hair® stainless steel.

PHOTO © A. ZAHNER COMPANY.

Ti-Stainless or PVD Coated Stainless is a high-performance surface that can be used to achieve gold, copper, bronze, and brass tones in stainless steel.

PHOTO © A. ZAHNER COMPANY.

A stainless steel ImageWall installation at the Gould-Evans-designed DeBruce Center at the University of Kansas.

PHOTO © A. ZAHNER COMPANY.

Stainless steel doesn’t promote bacterial growth, nor does it provide a surface for bacteria to collect and flourish. Most stainless steel surfaces are as easy to clean as glass or ceramic surfaces. This is because the surface does not develop a roughened oxide nor is it very porous. Removal of soils and bacteria using common cleaners is possible with stainless steel surfaces. Seams, where substances can be trapped, can be eliminated, or designed around by considering a welded and polished joint, making a monolithic, seamless surface. Tests on stainless steel surfaces have shown the washing time versus the number of bacteria remaining on a surface is reduced in stainless steel when compared to enamels, polycarbonate, and mineral resin surfaces after simulated wear tests.6

A polished stainless steel surface should be considered in areas where concerns for bacteria accumulation are elevated such as public restrooms. Since it is easy to clean using harsh chemicals, stainless steel can be used for urinal screens, toilet partitions, door handles, and countertops.

The feature wall at Laura Gambucci boutique features black interference stainless steel.

Angel Hair stainless steel is combined with flat seam and ZEPPS technology for the NASCAR Hall of Fame by Pei, Cobb, Freed architects.

PHOTO © A. ZAHNER COMPANY.

Recycling of stainless steel has grown dramatically and has become the main raw source of the metal. The International Stainless Steel Forum states that objects today made of stainless steel have an average recycling content of approximately 60%.

The value of stainless steel scrap is higher than steel thus very little makes it to the trash heap. In addition, objects and surfaces created from stainless steel have a long-projected life cycle. Once the useful life is over, the stainless steel most certainly will be recycled. Because stainless steel is rarely coated with paint, it can be readily recycled and put back to use.

The combination of longevity and the ability to recycle stainless steel make it exceptional among materials used in art and architecture.

Steel

Brown University Applied Math Building, clad in Zahner Solanum Weathering Steel.

Iron compounds are found throughout our environment. It is an important element for human and animal life. In fact, all animal life on earth depends on some level of iron consumption. For humans and many animals, iron is a central component of hemoglobin, a protein in the blood. Humans need iron to transfer oxygen and for muscle metabolism.

Having the proper level of iron helps avoid an iron deficiency which can lead to fatigue, anemia, and diseases of the bone.

Plants need very little iron but this small amount is necessary for plant health. Iron is used in the production of chlorophyll, which gives a plant color and is necessary for a plant to thrive.

Marlon Blackwell Architects’ Arkansas House features a preweathered weathering steel facade system.

PHOTO © TIM HURSLEY COURTESY OF MARLON BLACKWELL.

A carbon-steel wall art feature designed by Make Studios.

PHOTO © MAKE STUDIOS, PHOTOGRAPHED BY NATHAN WEBER.

In the built world, iron is ubiquitous. It offers longevity and can be melted and reused indefinitely. The recycling of iron and steel is well established around the world.

Specialized mills with electric arc furnaces have helped increase the demand for recycling as well as reduced the energy consumption of steel production. The energy required to recycle scrap is approximately a third of the energy required from the ore production route.7

Zinc

The facade and soffit of the McMurtry Building in Stanford, CA, featuring preweathered Baroque Zinc™ patina.

PHOTO © A. ZAHNER COMPANY.

Zinc is a necessary element for human and animal life. Approximately 15 milligrams of zinc is needed each day. Next to iron, zinc is one of the most important metals needed for proper development.

Zinc is used by the body to create the enzymes needed for cell growth and aids in liver and kidney functioning as well as healing, fending off fatigue, and even fighting the common cold.

Both zinc and its oxide are not considered harmful to humans or animal life in light and moderate exposure. The low toxicity of zinc enables it to be used for everything from burns to diaper rash. Most commonly it is used as sunscreen to protect against harmful ultraviolet radiation as well as topical anti-inflammation cream to combat insect bites and poison ivy. The maximum amount of zinc oxide in these various ointments is approximately 25%.

Institute for Contemporary Art at VCU, designed by Steven Holl Architects, features a zinc facade.

PHOTO BY TEX JERNIGAN, ARKO | © A. ZAHNER COMPANY

The Hunter Museum features Zahner’s preweathered Hunter Zinc™.

Zinc is essential for the development of young children. Too little zinc will affect the immune system and development of several body functions from reproduction to growth.

When zinc is in the soil, it will usually combine with other substances. That is one of the reasons we do not see zinc in its pure form naturally. Plants require zinc to grow, but in very small amounts. As such,. zinc is considered a micronutrient for the health of plants.

Zinc by itself is not particularly toxic. Zinc ore, though, is often accompanied by lead, cadmium, and arsenic. Early mining was focused on lead and the zinc was considered a nuisance and quickly discarded.

Lead contamination, along with other contaminants such as cadmium and arsenic, lingers today—long after the mining and smelting operations have ceased. Most of these antiquated operations are no longer in business but the scar left is still there.

Preweathered Baroque Zinc™ is appropriate for interior and exterior use.

PHOTO © A. ZAHNER COMPANY.

Zinc B001, a concept surface from Zahner, is a preweathered zinc patina that rivals the appearance of blackened steel.

PHOTO © A. ZAHNER COMPANY.

Today, using zinc as a coating of steel in the process known as galvanizing is considered an environmental and sustainable coating process. There are no VOCs (volatile organic compounds) released during the process. Furthermore, it results in a steel product that will last longer and have far less maintenance when properly done as compared to paint coatings. The initial cost of galvanizing is very low as well.

On top of all this, the steel and the zinc can be recovered and recycled. Recycling of existing zinc currently stands at about 30% and is expected to increase as new systems of recovery bring the cost of recycling down. Recycling zinc from sheet, scrap zinc, and stamped zinc is relatively straight forward. As the steel is heated, the zinc melts and vaporizes. From the vapors, the zinc is removed and repurposed. Another method is to remove the zinc by leaching the metal with acid and electrowinning to recover the metal out of the acid bath.

Architectural metals offer many unique advantages when it comes to designing and building with sustainability in mind. For more on the metals discussed here, explore the Architectural Metal Series, written by L. William Zahner and published by John Wiley and Sons.

- Aluminum Surfaces: A Guide to Alloys, Finishes, Fabrication and Maintenance in Architecture and Art

- Copper, Brass, and Bronze Surfaces: A Guide to Alloys, Finishes, Fabrication, and Maintenance in Architecture and Art

- Stainless Steel Surfaces: A Guide to Alloys, Finishes, Fabrication and Maintenance in Architecture and Art

- Steel Surfaces: A Guide to Alloys, Finishes, Fabrication, and Maintenance in Architecture and Art

- Zinc Surfaces: A Guide to Alloys, Finishes, Fabrication, and Maintenance in Architecture and Art

References

- Data from the International Aluminum Association

- Kuhn, P.J., Doorknobs: a source of nosocomial infection? Diagnostic Medicine, 1983.

- J.O. Noyce, etal., Potential use of copper surfaces to reduce survival of epidemic methicillin-resistant Staphylococcus aureus in the healthcare environment. Journal of Hospital Infection, 63, p 289-287, 2006

- P. 531-541; A Screening level risk assessment of waterborne copper in the San Francisco Bay Area, USA.; Copper 2003 Health, Environment and Sustainable Development, VII. Proceedings from the Copper 2003 The 5th International Conference, November 30-December 3, 2003. Santiago, Chile.

- Young, 1992, p.108

- UK, Journal of Applied Bacteriology

- P.47 – 49, The Book of Steel, 1996, Intercept Ltd.; Beranger, G., Henry, G., Sanz, G.