Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

It’s fundamental to the ethos of curiosity and continuous improvement that has been cultivated over the course of the 125-year history of the company.

But why the deep dive into the mundane world of shipping crates?

Like most new initiatives or inventions, it was born of necessity.

On a recent field trip to a project site, Jordan Colwell, process engineer and 10-year Zahner veteran, noticed numerous challenges with Zahner’s current shipping crate designs. Though well-designed to safely and securely transport Zahner’s architectural metals and fabrications to the job site, once there they became more of a hindrance for a number of reasons.

Colwell noticed immediately the effects of weather, handling, and various other job site elements on shipping crate signage and labels. Missing or illegible labels meant there was no way for construction crews or installers to tell what was inside the opaque boxes of plywood. This also impacted the accuracy and efficiency of installation since most Zahner pieces are like gigantic pieces of a puzzle that have an exact order and sequence of installation.

Expense and sustainability were two other immediate concerns. Plywood, fasteners and the skilled labor to build the crates add up quickly, driving some crating expenses easily into the tens of thousands of dollars.

And most of the time these crates are single-use containers that must be disposed of on the job site which means more lumber going into landfills, or being hauled off to reclamation centers.

“We knew this was a problem worth tackling so we brought it back to company leaders and everyone decided we should run a contest to come up with the best new shipping crate designs,” Colwell said. “Not only could it help our clients and contractors on job sites, but it could also be a good way to foster camaraderie and collaboration within Zahner.”

A Little Friendly Co-Opetition

Teams were organized, judging criteria were established, and prizes of PTO and cash were promised to the winners. Teams were required to be multidisciplinary so “dream teams” of designers and engineers-only were prohibited. Finance, sales, engineering and operations were represented on each team.

The crate competition scorecards rated teams on a number of design, constructability, expense, and sustainability criteria. Design concepts were also rated relative to existing crating solutions. Judges scored concepts based on if they thought the designs were equivalent to the current method; better than the current method; or less efficient than the current method.

Obvious attributes such as protective qualities, weight, weather-resistance, size and shape figured heavily into final scores. Stacking, storage, and reusability also played a big part in the judges final decisions.

And the Winner Is…

The depth and variety of the new crating ideas and solutions were impressive. From new wood designs, and plastic modular blocks, to creative combinations of rubber, steel and aluminum, all the teams brought their best.

The scoring was tight among the four finalists, and the winning design was created by team “Big Country” made up of Derek Rehm, Travis Rowe and Scott Ludwig. Big Country gained big points with judges in a few key areas that set them apart from the others, including “Protectivity,” “Stacking and Storage,” “Re-usability,” and “Fasteners.”

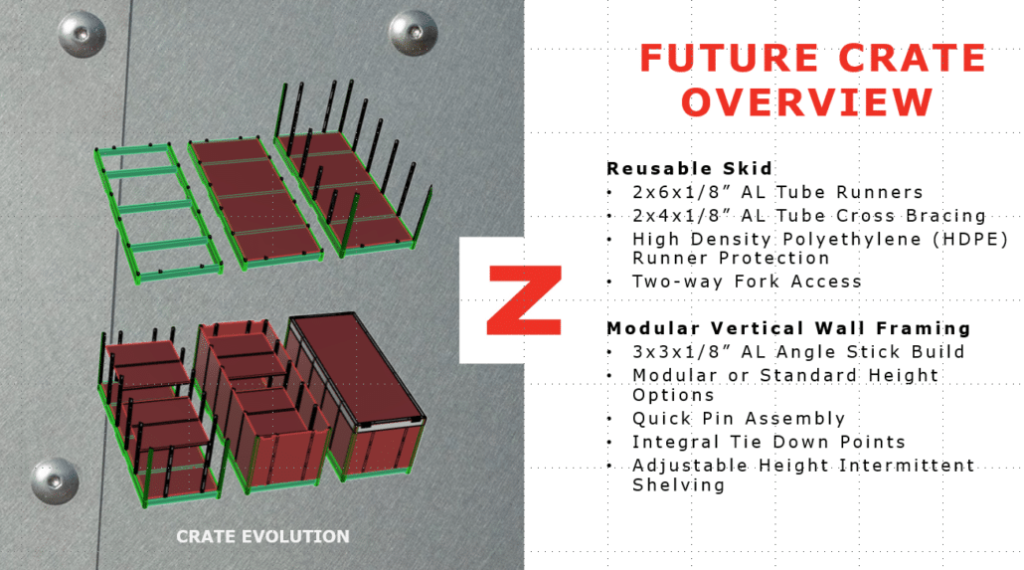

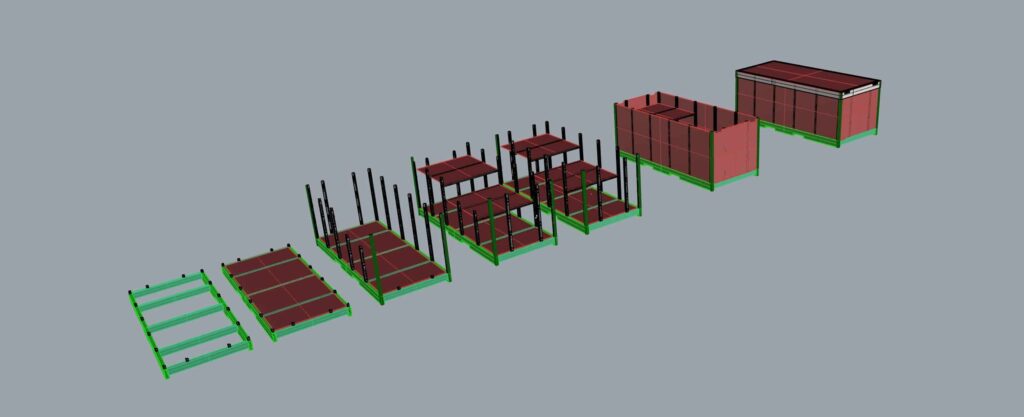

The Big Country design featured aluminum tube framing and cross-bracing, adjustable aluminum internal shelving and quick-pen fasteners, all wrapped in a high density polyethylene (HDPE) weatherproof skin. Judges seemed to give Big Country an edge for their approach to stackability, breakdown, and return packing and strapping.

Colwell said the winning crate design is now being adapted and integrated into the Zahner process for current and future projects. New Zahner shipping crates will help job site contractors stay better organized, make it easier to find parts in the proper sequences, and allow Zahner to reuse these crates up to an estimated 10 times – much more cost-effective and environmentally-friendly than the single-use designs employed today.

And the healthy internal competition has been a valuable exercise in problem-solving and team-building.

“Everyone had fun, we learned some interesting things along the way, and we ended up coming up with a much improved design that’s good for clients, contractors, and the environment,” Colwell said. “It was a great experience and taught us that no problem is too big or too small and when you work at innovation, it eventually pays off and begins to work for you.”

See pictures of the winning design below.