Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

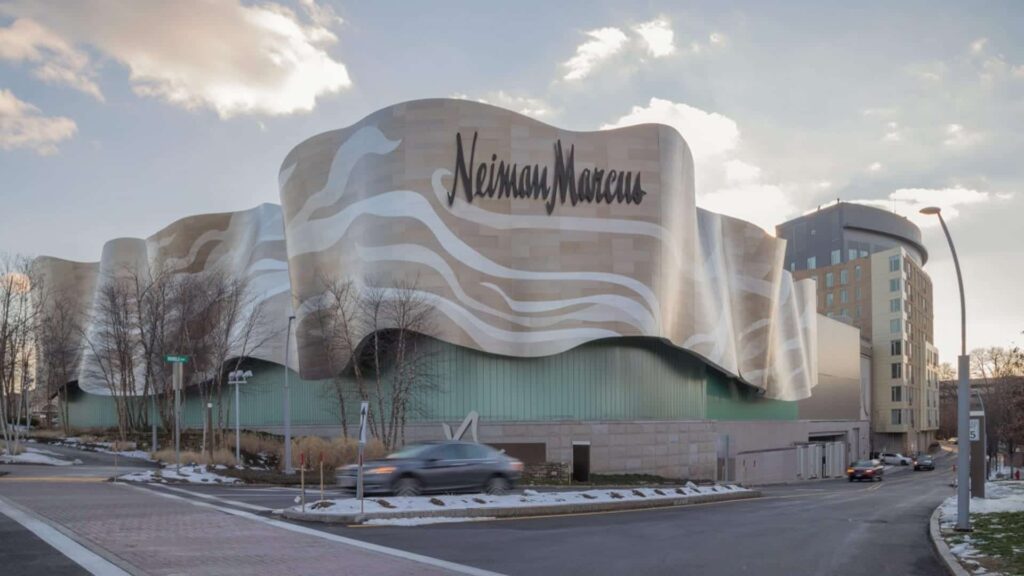

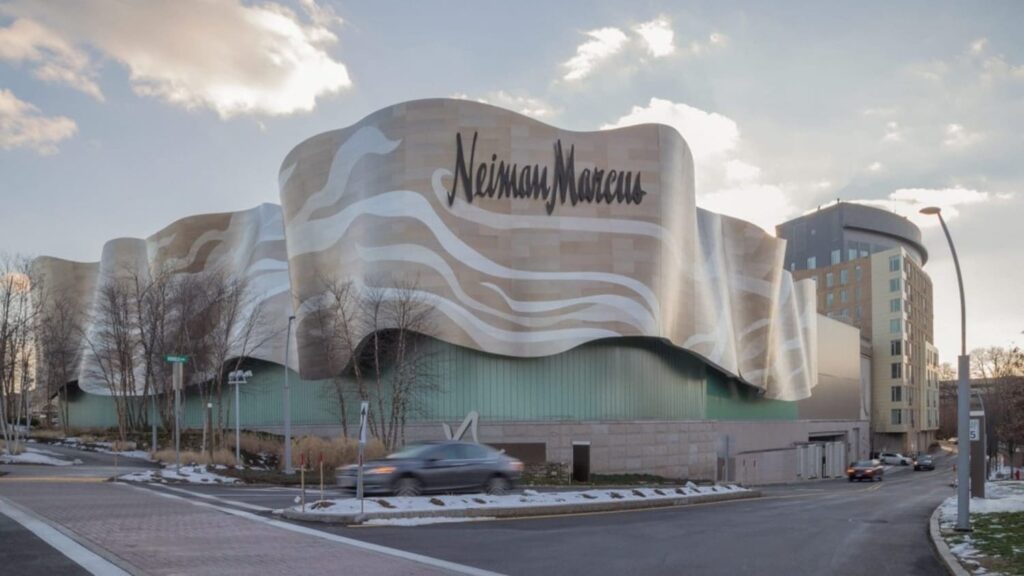

In the mid-1970’s architect Howard Elkus and his wife designed a silk dress for her to wear to a cocktail party. Three decades later Elkus, a partner at Boston’s Elkus-Manfredi Architects, drew on it for his radical design of the Natick, Massachusetts, Neiman Marcus building, completed in 2007.

The building’s 570-foot-long undulating stainless steel façade, in tones of bronze, champagne and silver, “waves in and out and top to bottom almost as if someone was wearing a dress and walking,” said Elkus.

The stainless steel fabric is made up of several thousand individual skins that interlock to create the colored pattern. They began as 18 gauge sheets of about 48 by 120 inches, and overlap like the shingles of a roof to shed water.

The sheets are affixed with ¾ inch custom stainless steel fasteners into extruded aluminum shapes produced by A. Zahner Company, a Kansas City firm specializing in architectural metals.

PHOTO © A. ZAHNER COMPANY.

It took a year to design, engineer, and fabricate the 67 panels and another three months to install them.

Bill Zahner, the firm’s chief executive, said the panels are designed to take tremendous wind loads—like those on an airplane—and are “not unlike what we used when we created Chicago’s Millennium Park bandshell for Frank Gehry.”

The bronze and champagne colors were created by controlling waves of light by embossing the stainless steel with abrasive glass beads and immersing the metal in a bath of chromium acid to expedite oxidation. The result was modifying the reflectivity by altering the metal’s thickness.

The largest of the sheets were 8 feet 6 inches wide and 40 feet tall. All of the work was computer modeled in either Pro/Engineer or CATIA so those involved could see three dimensionally how the components fit.

The metal was formed using the Zahner Engineered Profile Panel system, also known as ZEPP, developed by Tony Birchler and Bill Zahner, which essentially uses a contour model of the building face to define where the skins attach.

Different tools and methods were used to manipulate the metals depending upon how much curvature it had and how much more was needed.

It took a year to design, engineer, and fabricate the 67 panels and another three months to install them, leaving the New England town with an iconic structure, part of the fourth-largest mall on the East Coast.

Excerpted with permission from Susan Chaityn Lebovits‘ article, Pret a Porter which appeared in Form Magazine.